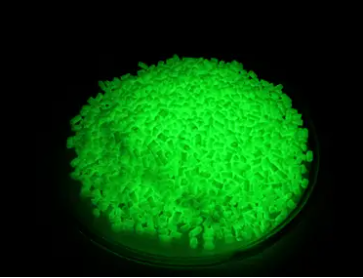

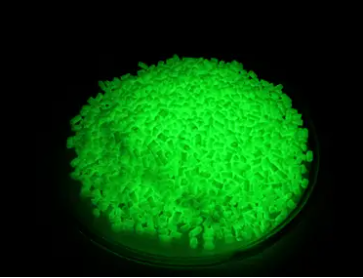

What is Glow Masterbatch

Glow masterbatch is a plastic masterbatch with luminescent function. It is a luminescent powder deeply processed with a transparent plastic. The masterbatch is directly used, or it is mixed with raw materials of the same color to make various glow masterbatch products. These plastic products have the characteristics of general plastics, and luminescent products have a high artistic value. They can absorb all kinds of visible light for 10-30 minutes and emit light in the dark for more than 10 hours. The development of glow masterbatch has seriously solved the pollution of luminescent powder on plastics such as coloring and blackening, and has been recognized and used by more and more injection molding customers.

Usage Instructions for Glow Masterbatch

In general, glow masterbatch should not have regrind material added to it.

Including the regrind material in the glow masterbatch will darken the color; high amount of regrind material can even blacken the color.

The addition of regrind material to the glow masterbatch will significantly decrease the brightness of the luminescent, typically ranging from 20% to 50% if the lab proportion is relatively small.

It will increase the brittleness of the product, reduce the toughness of the product, and be difficult to demould in severe cases. Therefore, it is not recommended to add the recycled material during the production. The reason for the reverse mold is that the organic color masterbatch and inorganic powder are separated from each other. If the cost is also considered, a small amount of recycled material can be added, but it is necessary to try out the appropriate percentage.

Secondly, certain issues should be noted when using glow masterbatch:

It would be better to choose the old machines and old and short screws while making a selection for luminescent products (usually suggesting the machine head within 0.8 meters).

The glow masterbatch drying time has to be elongated for one hour to make sure to get rid of all the moisture. The temperature can be the same or a little higher from 1 up to 5 degrees compared to standard materials.

During the procedure of injection molding, maintain the front temperature constant while decreasing the temperature of the behind and middle sections. This is incredibly important for the application of PC. It is suggested to set the rear temperature to around 220 degrees Celsius or as low as possible within the injection range.

If the luminous masterbatch requires color mixing, reduce the mixing speed and time of the color mixing machine appropriately.

English

English