At Hangzhou Junting Luminescence Technology Co., Ltd., we are proud to share the advancements we have achieved in the field of functional photoluminescent materials. Since our founding we have remained committed to research, innovation, and environmental responsibility. Today our thermoplastic photoluminescent coatings are being recognized as a preferred solution in transportation and safety sectors around the world. With increasing adoption in both domestic and international markets, this product has become a cornerstone of our mission to improve visibility and safety in modern infrastructure.

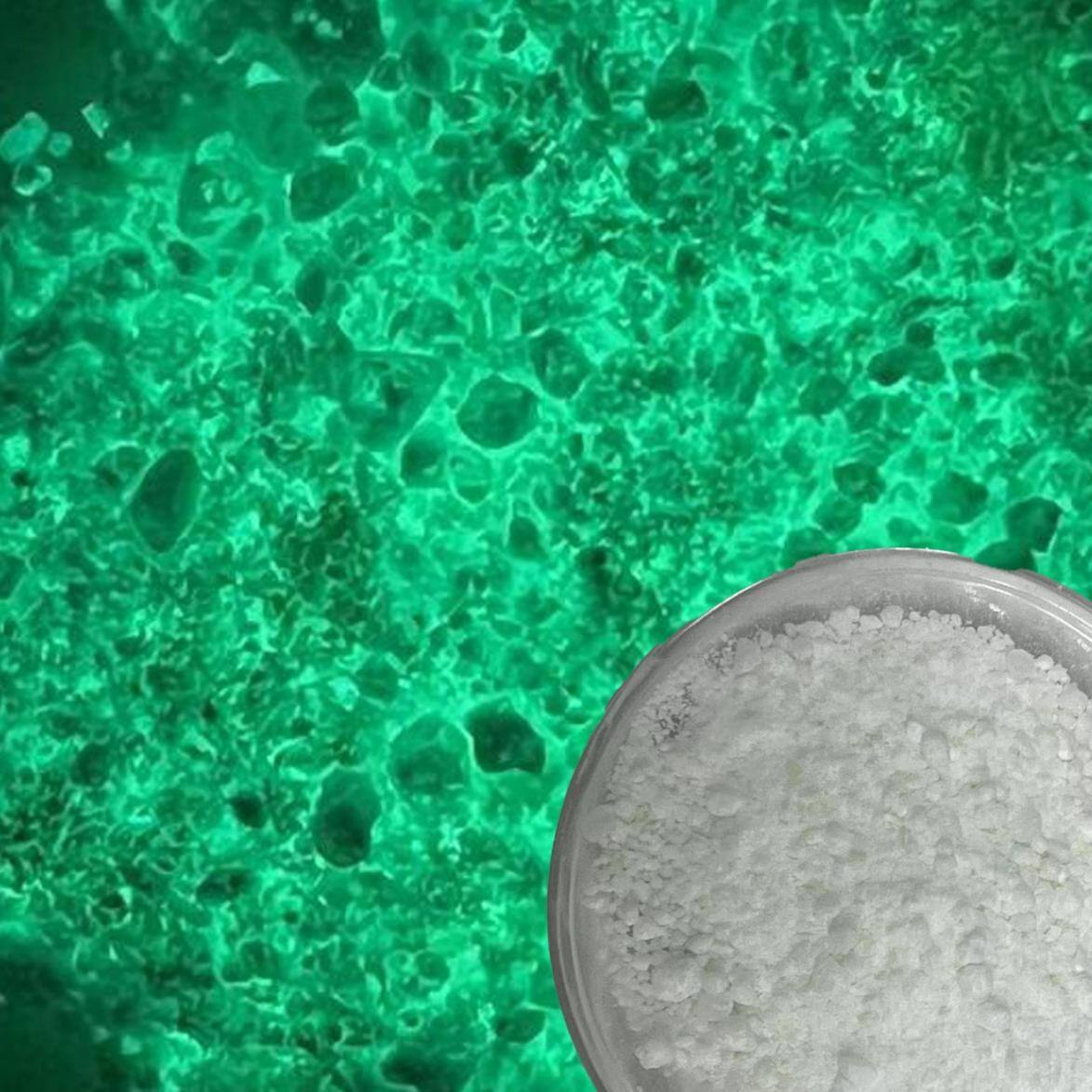

Our thermoplastic photoluminescent coatings use rare earth aluminate as the primary luminescent matrix. We incorporate europium and dysprosium to optimize energy storage efficiency, creating a high performance material that absorbs visible light within five to fifteen minutes and emits a consistent afterglow for more than twelve hours. The initial brightness exceeds fifteen hundred millicandelas per square meter which ensures that road users can clearly identify markings in critical low visibility situations. Even in rainy or foggy weather, these markings remain visible at distances of up to two hundred meters. This capability strengthens traffic guidance, supports emergency response and enhances overall road safety.

Durability is a central part of our engineering philosophy. We understand that road materials must withstand constant pressure, friction, and wide temperature variations. In response our research team developed a composite system that combines modified thermoplastic resin with nano silica. This combination creates a strong and stable coating that resists abrasion and performs reliably across extreme temperature cycles. Our materials have passed rigorous testing from minus thirty degrees Celsius to eighty degrees Celsius without losing structural or luminescent performance. In real world applications the coating has a service life that exceeds eight years. This long lifespan reduces maintenance costs and ensures consistent performance for road authorities and end users.

Environmental protection remains one of our core commitments. We design our materials to be safe both for users and for the environment. Our thermoplastic photoluminescent coatings do not contain volatile organic compounds or radioactive substances. They produce no irritating odors and pose no health risks during or after application. After construction the coating becomes tire dry within five minutes which allows roads to reopen quickly and prevents project delays. This level of efficiency is especially valuable during high traffic hours or in urban areas where road closures cause significant congestion.

To ensure wide applicability we have made our coatings compatible with mainstream construction methods. The product supports thermoplastic extrusion, screeding, and spray based processes commonly used in large scale road marking projects. This has allowed our materials to be adopted in many different environments, including highways, tunnels, urban greenways, fire access routes, pedestrian pathways and emergency escape systems. These applications highlight the dual purpose of our product which serves both as a traffic guidance tool and as a reliable emergency visibility solution.

We believe that technical support is essential to the success of our clients. For this reason, our professional team offers brightness customization and on site or remote guidance for construction teams. Every project has its own requirements and certain environments demand specific levels of luminescent intensity. We work closely with our clients to adjust formulations and ensure compatibility with their selected substrates and equipment. This level of support helps our partners achieve optimal performance and long term reliability in their projects.

Our production facilities remain one of our strongest assets. With a one thousand meter production base equipped with advanced machinery we ensure stable supply and consistent quality. Every batch undergoes strict quality control inspections from raw materials to finished products. We follow standardized procedures that align with national and international certification requirements. As a result our coatings have passed authoritative standards including JT/T967-2023 and JT/T18226-2022. Meeting these benchmarks has strengthened our credibility and allowed us to participate in major global transportation and safety initiatives.

We continue to operate under the belief that safe illumination can empower communities and improve daily life. Our guiding principle of “Safe Illumination and Green Empowerment” reflects our dedication to sustainable growth and technological progress. By offering clean, safe and high performance photoluminescent materials we aim to support the development of smart transportation systems and future oriented emergency infrastructure.

Looking ahead, we see tremendous potential for photoluminescent materials in the era of smart cities. With growing interest in intelligent highways, autonomous driving, and environmentally conscious development, the demand for advanced visibility solutions is expected to rise. We are committed to expanding our collaborations with domestic and international partners, participating in more infrastructure projects and continuing to push the boundaries of material science.

At Junting we take pride in the trust and recognition we have received from customers worldwide. We remain focused on innovation, quality and long term reliability. Our thermoplastic photoluminescent coatings represent more than a technological achievement. They reflect our broader mission to create safer, brighter and more sustainable pathways for communities everywhere.

Copyright © 2026 Hangzhou Junting Luminescence Technology Co., Ltd. All rights reserved.