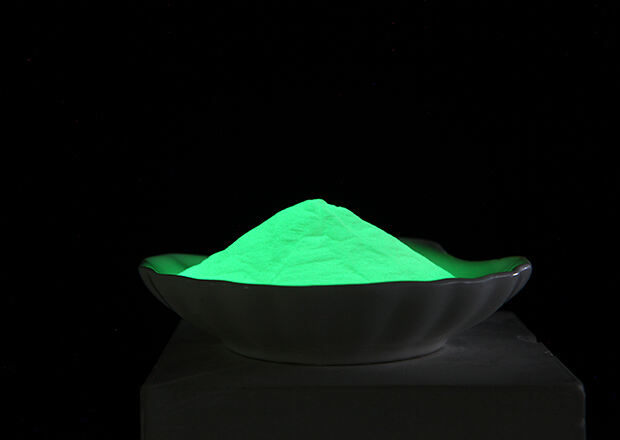

The demand for luminescent materials has surged across various industries, with strontium aluminate glow powder emerging as the superior choice for applications requiring long-lasting, bright phosphorescent properties. This advanced photoluminescent material offers exceptional performance compared to traditional zinc sulfide-based alternatives, making it essential for manufacturers, distributors, and end-users to understand the sourcing landscape. Finding reliable suppliers who can deliver consistent quality and meet specific application requirements requires careful evaluation of multiple factors including certification standards, manufacturing capabilities, and supply chain reliability.

Understanding Strontium Aluminate Glow Powder Applications

Industrial and Commercial Applications

Industrial applications for strontium aluminate glow powder span numerous sectors where safety and visibility are paramount. Emergency egress systems in commercial buildings utilize this material for exit signs, pathway markers, and stairwell illumination that remains visible during power outages. The automotive industry incorporates these phosphorescent materials into dashboard components, gear shift indicators, and safety equipment where reliable glow-in-the-dark functionality is crucial. Manufacturing facilities often specify strontium aluminate compounds for equipment marking, safety zone delineation, and hazard identification systems.

The construction industry has embraced strontium aluminate glow powder for architectural applications including decorative concrete, terrazzo flooring, and facade elements that provide ambient lighting effects. Marine applications benefit from the material's resistance to moisture and salt exposure, making it ideal for deck markers, life safety equipment, and navigational aids. These diverse applications require suppliers who understand specific performance requirements and can provide customized formulations to meet industry standards.

Consumer and Novelty Markets

Consumer applications represent a significant market segment for strontium aluminate glow powder, particularly in arts and crafts, toys, and decorative items. Craft manufacturers incorporate these materials into paints, plastics, and textiles to create products with extended afterglow periods that far exceed traditional phosphorescent materials. The toy industry values the non-toxic nature and superior brightness of strontium aluminate compounds for creating safe, long-lasting glow effects in children's products.

Home decoration markets have seen increased demand for glow powder applications in garden stones, pathway markers, and artistic installations. Event planners and entertainment venues utilize these materials for creating atmospheric effects, stage designs, and temporary installations that maintain visibility without electrical power. Understanding these diverse market segments helps buyers identify suppliers who specialize in their specific application requirements.

Quality Standards and Certification Requirements

International Standards and Compliance

Quality assurance in strontium aluminate glow powder sourcing requires adherence to international standards including ISO certifications, ASTM testing protocols, and regional compliance requirements. European suppliers must meet REACH regulations for chemical safety, while North American suppliers should comply with EPA and FDA guidelines depending on the intended application. These certifications ensure that materials meet safety standards for human exposure and environmental impact.

Testing protocols for luminescent materials include photometric measurements, particle size analysis, and chemical composition verification. Suppliers should provide certificates of analysis that document glow intensity, afterglow duration, and particle size distribution for each batch. Quality management systems like ISO 9001 certification indicate a supplier's commitment to consistent quality control processes and continuous improvement in manufacturing operations.

Performance Testing and Validation

Comprehensive performance testing validates the suitability of Strontium Aluminate Glow Powder for specific applications through standardized measurement procedures. Photoluminescent intensity measurements using calibrated photometers establish baseline performance metrics that can be compared across different suppliers and product grades. Accelerated aging tests simulate long-term exposure conditions to predict material stability and performance degradation over time.

Environmental testing assesses material performance under various temperature, humidity, and UV exposure conditions that may be encountered in real-world applications. Chemical compatibility testing ensures that the glow powder maintains its properties when incorporated into different matrix materials such as plastics, paints, or ceramics. Suppliers who provide comprehensive testing data demonstrate their understanding of application requirements and commitment to product quality.

Supplier Evaluation Criteria

Manufacturing Capabilities and Capacity

Evaluating potential suppliers requires assessment of their manufacturing capabilities, production capacity, and quality control systems. Established manufacturers typically operate dedicated facilities with specialized equipment for synthesizing strontium aluminate compounds under controlled atmospheric conditions. Production capacity should align with projected demand requirements while maintaining flexibility for custom formulations and varying order quantities.

Quality control infrastructure including analytical laboratories, testing equipment, and qualified personnel demonstrates a supplier's ability to maintain consistent product quality. Manufacturing process documentation, standard operating procedures, and change control systems indicate systematic approaches to quality management. Suppliers should provide facility certifications, audit reports, and evidence of continuous improvement initiatives that support long-term supply relationships.

Technical Support and Customization

Technical support capabilities differentiate suppliers who can provide value-added services beyond basic product supply. Application engineering support helps optimize material selection, processing parameters, and integration techniques for specific end-use requirements. Custom formulation capabilities enable suppliers to modify particle size distributions, surface treatments, and additive packages to enhance performance in specialized applications.

Documentation support including technical data sheets, safety data sheets, and application guides facilitates proper material handling and processing. Training programs and technical seminars demonstrate supplier commitment to customer success and ongoing relationship development. Responsive technical support teams with expertise in photoluminescent materials provide valuable resources for troubleshooting and optimization activities.

Global Sourcing Strategies

Regional Supply Chain Considerations

Global sourcing of strontium aluminate glow powder requires understanding regional manufacturing capabilities, supply chain logistics, and regulatory environments. Asian manufacturers, particularly in China and Japan, represent significant production capacity with established expertise in rare earth processing and phosphor synthesis. European suppliers often specialize in high-purity grades and custom formulations for demanding applications in aerospace, medical, and precision industries.

Transportation considerations include material stability during shipping, packaging requirements for powder materials, and regulatory compliance for international trade. Lead times vary significantly between regions, with local suppliers offering shorter delivery schedules while international suppliers may provide cost advantages for larger volumes. Currency fluctuations, trade policies, and geopolitical factors can impact long-term supply arrangements and pricing stability.

Supply Chain Risk Management

Effective risk management strategies for strontium aluminate glow powder sourcing include supplier diversification, inventory management, and contingency planning. Multiple supplier relationships reduce dependency risks while providing leverage for pricing negotiations and quality improvements. Strategic inventory levels balance carrying costs against supply disruption risks, particularly for critical applications where material availability directly impacts production schedules.

Supply chain monitoring systems track supplier performance metrics including on-time delivery, quality conformance, and responsiveness to technical inquiries. Regular supplier audits and relationship reviews identify potential risks early and maintain alignment between buyer requirements and supplier capabilities. Force majeure planning addresses potential disruptions from natural disasters, regulatory changes, or market volatility that could impact material availability.

Cost Optimization and Procurement Strategies

Pricing Models and Contract Structures

Understanding pricing structures for strontium aluminate glow powder helps optimize procurement costs while maintaining quality standards. Volume-based pricing typically offers significant cost reductions for larger quantities, making consolidation of requirements across multiple product lines or business units advantageous. Annual contracts with predetermined volumes can provide price stability and preferred allocation during market shortages.

Raw material cost components including rare earth elements, processing chemicals, and energy costs influence pricing volatility and long-term trends. Suppliers who provide cost transparency and regular market updates enable better forecasting and budget planning. Index-based pricing mechanisms tied to commodity prices can provide fair allocation of market risks between buyers and suppliers while maintaining long-term partnership relationships.

Total Cost of Ownership Analysis

Total cost of ownership evaluation extends beyond unit price to include quality-related costs, logistics expenses, and operational impacts. Higher-quality materials may command premium pricing but deliver superior performance, longer service life, and reduced warranty claims that offset initial cost differences. Processing characteristics such as dispersibility, flowability, and compatibility can impact manufacturing efficiency and yield rates.

Logistics costs including packaging, shipping, handling, and inventory carrying costs contribute significantly to total acquisition costs. Local suppliers may offer cost advantages through reduced transportation expenses and shorter lead times, while international suppliers might provide economies of scale for larger volume requirements. Value-added services such as technical support, custom packaging, and just-in-time delivery can justify premium pricing through operational benefits.

FAQ

What is the typical glow duration for high-quality strontium aluminate glow powder

High-quality strontium aluminate glow powder typically provides visible afterglow for 8-12 hours after a 10-minute light exposure, with some premium grades maintaining detectable luminescence for up to 24 hours. The initial brightness immediately after light exposure can be 10-20 times brighter than zinc sulfide alternatives, with a gradual decay following a logarithmic curve. Performance varies based on particle size, crystal structure, and activator concentrations used in the manufacturing process.

How should strontium aluminate glow powder be stored to maintain quality

Proper storage requires dry, cool conditions away from direct sunlight and moisture exposure that can degrade phosphorescent properties over time. Sealed containers with desiccant packets help maintain optimal moisture levels below 1% relative humidity. Storage temperatures should remain below 25°C (77°F) to prevent thermal degradation, while avoiding freezing conditions that could cause particle aggregation. Rotation of inventory following first-in-first-out principles ensures materials are used within recommended shelf life periods.

What factors affect the price of strontium aluminate glow powder

Pricing factors include raw material costs for strontium carbonate and aluminum oxide, rare earth activator elements, and processing complexity required for specific grades. Higher purity levels, smaller particle sizes, and specialized surface treatments command premium pricing due to additional manufacturing steps and quality control requirements. Market demand, production capacity utilization, and regional supply-demand balance also influence pricing trends, with specialty grades typically maintaining higher margins than commodity products.

Can strontium aluminate glow powder be mixed with other materials

Strontium aluminate glow powder can be successfully incorporated into various matrix materials including plastics, paints, ceramics, and textiles through proper processing techniques. Compatibility depends on processing temperatures, chemical reactivity, and dispersion methods used during incorporation. Some applications may require surface-treated grades or encapsulated forms to prevent chemical interactions that could degrade luminescent properties. Loading levels typically range from 5-50% by weight depending on desired glow intensity and matrix material properties.