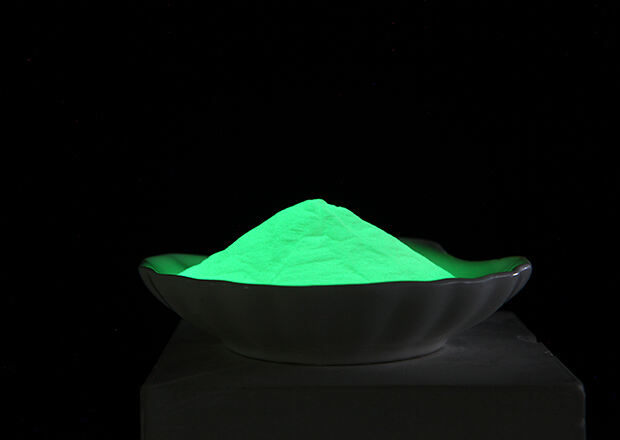

The fascinating world of photoluminescent materials has captured human imagination for decades, with strontium aluminate glow powder standing at the forefront of this revolutionary technology. This remarkable compound has transformed industries ranging from safety signage to decorative arts, offering unprecedented brightness and longevity compared to traditional phosphorescent materials. Understanding the intricate science behind how strontium aluminate glow powder functions reveals why it has become the gold standard for modern glow-in-the-dark applications across numerous sectors.

Understanding the Fundamental Chemistry of Photoluminescence

Molecular Structure and Dopant Integration

The extraordinary luminescent properties of strontium aluminate emerge from its unique crystalline structure, which serves as a host matrix for rare earth elements acting as activators and co-activators. The base compound, strontium aluminate (SrAl2O4), forms a stable crystal lattice that provides optimal spacing and energy levels for photon absorption and emission processes. When manufacturers introduce europium ions as the primary activator and dysprosium ions as the co-activator into this crystal matrix, they create energy centers capable of storing and slowly releasing photons over extended periods.

The integration of these dopant elements occurs during the high-temperature synthesis process, where precise control of atmospheric conditions and temperature profiles ensures uniform distribution throughout the crystal structure. This careful engineering results in a material with exceptional afterglow characteristics that far exceed conventional zinc sulfide-based phosphors. The europium ions occupy specific lattice positions within the strontium aluminate framework, creating localized energy states that facilitate the photoluminescent process through quantum mechanical interactions.

Energy Band Theory and Electron Excitation

The photoluminescent behavior of strontium aluminate operates according to well-established principles of energy band theory, where electrons transition between different energy levels within the crystal structure. When photons strike the material during the charging phase, electrons in the ground state absorb sufficient energy to jump to higher energy levels, creating what scientists term excited states. These elevated energy positions represent unstable configurations that naturally seek to return to lower energy states through various pathways.

The presence of trap levels within the energy band structure plays a crucial role in determining the duration and intensity of the afterglow phenomenon. These intermediate energy states, created by the dysprosium co-activator, act as temporary storage locations for excited electrons, preventing immediate recombination and enabling the characteristic long-lasting emission. The depth and distribution of these trap levels directly influence the decay characteristics of the luminescent output, with deeper traps corresponding to longer afterglow durations.

The Photoluminescence Process Mechanics

Charge and Discharge Cycles

The operational cycle of Strontium Aluminate Glow Powder begins with the absorption of ambient light energy, during which photons with sufficient energy promote electrons from their ground state to excited energy levels within the europium activator centers. This charging process occurs rapidly under normal lighting conditions, with the material reaching saturation within minutes of exposure to appropriate light sources. The efficiency of this charging phase depends on the spectral distribution of the incident light, with ultraviolet and blue wavelengths providing optimal excitation.

During the discharge phase, electrons trapped in intermediate energy levels gradually return to their ground state through thermal activation processes, releasing photons in the characteristic yellow-green emission spectrum. This controlled release mechanism enables the material to maintain visible luminescence for hours after the removal of the excitation source. The rate of electron release from trap levels follows predictable kinetic models, allowing manufacturers to engineer materials with specific afterglow characteristics tailored to particular applications.

Spectral Characteristics and Color Properties

The distinctive yellow-green emission of strontium aluminate glow powder results from electronic transitions within the europium activator ions, specifically the 4f-4f transitions that produce narrow-band emission spectra centered around 520 nanometers. This wavelength corresponds to the peak sensitivity of human vision under low-light conditions, making the material exceptionally effective for safety and emergency applications. The high spectral purity and intensity of this emission significantly exceed the performance of traditional phosphorescent materials.

Manufacturers can modify the emission characteristics by altering the dopant concentrations and introducing additional rare earth elements into the crystal matrix. While yellow-green remains the most common and efficient color, variations including blue, purple, and red emissions are achievable through careful control of the activator chemistry. These alternative colors typically exhibit different afterglow durations and intensities, reflecting the varying energy level structures associated with different rare earth dopants.

Performance Factors and Material Properties

Brightness and Duration Characteristics

The superior performance of strontium aluminate glow powder stems from its exceptional brightness levels and extended afterglow duration compared to conventional phosphorescent materials. Initial brightness levels can reach several hundred millicandela per square meter immediately after charging, with visible luminescence persisting for ten to twelve hours in optimal conditions. This represents a significant improvement over zinc sulfide-based materials, which typically provide only one to two hours of useful afterglow.

The decay characteristics of strontium aluminate follow a complex multi-exponential pattern reflecting the contribution of multiple trap levels within the energy band structure. The initial rapid decay phase occurs within the first hour, followed by a slower, more sustained emission phase that can continue throughout the night. This decay profile makes the material particularly suitable for emergency lighting applications where consistent visibility over extended periods is critical for safety purposes.

Environmental Stability and Longevity

Strontium aluminate glow powder demonstrates remarkable stability under various environmental conditions, maintaining its photoluminescent properties through thousands of charge-discharge cycles without significant degradation. The robust crystal structure resists moisture absorption and chemical attack, ensuring consistent performance in demanding applications. Temperature variations within normal operating ranges have minimal impact on the afterglow characteristics, making the material suitable for both indoor and outdoor applications.

The long-term stability of strontium aluminate glow powder results from the inherent stability of the rare earth dopants within the crystal lattice and the absence of chemical reactions that could compromise the luminescent centers. Unlike organic phosphors that may degrade through oxidation or photochemical processes, the inorganic nature of strontium aluminate ensures predictable performance over extended service lives. Proper formulation and processing techniques can yield materials with operational lifetimes measured in decades rather than years.

Manufacturing and Quality Control Processes

Synthesis Methods and Temperature Control

The production of high-quality strontium aluminate glow powder requires precise control of synthesis conditions, beginning with the careful preparation of raw materials and extending through high-temperature processing stages. Manufacturers typically employ solid-state reaction methods, where stoichiometric mixtures of strontium carbonate, aluminum oxide, and rare earth oxides undergo calcination at temperatures exceeding 1200 degrees Celsius. The controlled atmosphere during synthesis prevents unwanted oxidation states and ensures optimal dopant incorporation.

Advanced manufacturing facilities utilize sophisticated temperature profiling and atmosphere control systems to maintain consistent conditions throughout the synthesis process. The cooling rate following high-temperature treatment significantly influences the final crystal structure and luminescent properties, requiring careful optimization to achieve maximum performance. Quality control measures include spectroscopic analysis, particle size distribution measurements, and standardized afterglow testing to ensure batch-to-batch consistency.

Particle Engineering and Surface Treatments

The physical characteristics of strontium aluminate glow powder particles play crucial roles in determining application performance and processing compatibility. Manufacturers employ various grinding and classification techniques to achieve specific particle size distributions optimized for different end-use requirements. Fine particles provide better dispersion and surface coverage in coatings, while coarser grades offer enhanced brightness and extended afterglow duration in bulk applications.

Surface treatment processes enhance the compatibility of strontium aluminate glow powder with various binder systems and improve moisture resistance in demanding environments. These treatments may include silane coupling agents, protective coatings, or surface functionalization to promote adhesion and prevent agglomeration during storage and processing. Advanced encapsulation techniques provide additional protection against chemical attack while maintaining the essential photoluminescent properties.

Applications and Industry Implementation

Safety and Emergency Systems

The exceptional performance characteristics of strontium aluminate glow powder have revolutionized emergency egress systems and safety signage applications across numerous industries. Building codes increasingly specify photoluminescent materials for exit signs, pathway marking, and emergency equipment identification, where reliable visibility during power outages can be life-saving. The long afterglow duration and high initial brightness ensure adequate illumination for safe evacuation procedures even in complete darkness.

Marine and aerospace applications leverage the reliability and environmental stability of strontium aluminate glow powder for critical safety systems where traditional lighting may fail. Aircraft manufacturers incorporate photoluminescent materials into cabin lighting systems, emergency equipment marking, and evacuation slide components. Similarly, maritime applications include life jacket indicators, emergency equipment marking, and deck safety systems that must perform reliably in harsh ocean environments.

Decorative and Consumer Products

Beyond safety applications, strontium aluminate glow powder has enabled innovative decorative products and consumer goods that capitalize on its superior luminescent properties. Architectural applications include decorative concrete, terrazzo flooring, and artistic installations that create stunning visual effects while providing functional illumination. The material's compatibility with various polymer systems allows manufacturers to create injection-molded products, flexible films, and textile coatings with embedded luminescent properties.

The crafting and hobby market has embraced strontium aluminate glow powder for creating unique artistic pieces, educational demonstrations, and entertainment products. Its non-toxic nature and easy incorporation into various media make it accessible to artists and craftspeople seeking to explore luminescent effects. Commercial products ranging from toys and novelties to high-end art pieces demonstrate the versatility and appeal of this remarkable material.

FAQ

How long does strontium aluminate glow powder continue to emit light after charging

Strontium aluminate glow powder typically maintains visible luminescence for 8 to 12 hours after a full charge, with the exact duration depending on the specific formulation, particle size, and environmental conditions. The initial bright glow gradually diminishes following a predictable decay curve, with useful visibility extending well into the night hours. Higher quality grades and optimized formulations can achieve even longer afterglow periods, making them ideal for applications requiring extended illumination periods.

What light sources work best for charging strontium aluminate glow powder

While strontium aluminate glow powder can be charged by various light sources, ultraviolet and blue light wavelengths provide the most efficient charging. Direct sunlight, fluorescent lights, and LED sources all effectively charge the material, with full saturation typically achieved within 10 to 30 minutes of exposure. The charging efficiency depends on the light intensity and spectral distribution, with higher energy photons enabling faster and more complete energy storage in the luminescent centers.

Is strontium aluminate glow powder safe for use in consumer products

Strontium aluminate glow powder is considered safe for use in consumer products when properly formulated and applied according to established guidelines. The material is non-radioactive and does not contain harmful heavy metals like some older phosphorescent compounds. However, as with any fine powder, appropriate handling precautions should be observed during manufacturing and processing to prevent inhalation of particles. Finished products containing properly encapsulated strontium aluminate pose no health risks under normal use conditions.

Can strontium aluminate glow powder be mixed with different materials and coatings

Strontium aluminate glow powder demonstrates excellent compatibility with a wide range of binder systems and coating formulations, including acrylics, polyurethanes, epoxies, and silicones. The key to successful incorporation lies in proper dispersion techniques and appropriate loading levels that balance luminescent performance with mechanical properties. Surface-treated grades offer enhanced compatibility and prevent settling or agglomeration in liquid systems, while maintaining the essential photoluminescent characteristics that make this material so valuable across diverse applications.

Table of Contents

- Understanding the Fundamental Chemistry of Photoluminescence

- The Photoluminescence Process Mechanics

- Performance Factors and Material Properties

- Manufacturing and Quality Control Processes

- Applications and Industry Implementation

-

FAQ

- How long does strontium aluminate glow powder continue to emit light after charging

- What light sources work best for charging strontium aluminate glow powder

- Is strontium aluminate glow powder safe for use in consumer products

- Can strontium aluminate glow powder be mixed with different materials and coatings