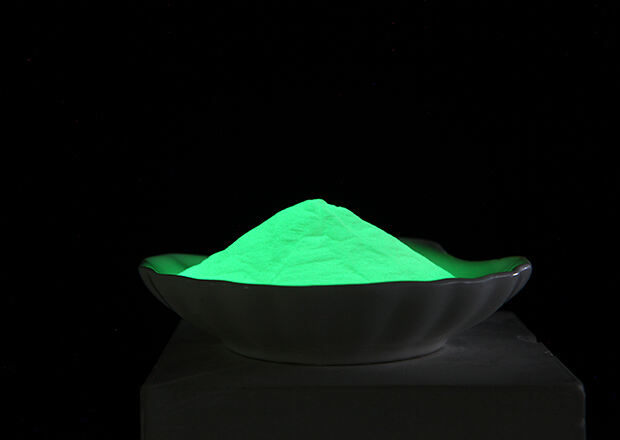

Strontium Aluminate Glow Powder represents a revolutionary breakthrough in photoluminescent technology, offering unprecedented brightness and longevity that surpasses traditional zinc sulfide alternatives. This advanced luminescent material has transformed industries ranging from safety applications to artistic endeavors, providing sustainable illumination without requiring electrical power. The unique crystalline structure of strontium aluminate enables it to absorb ambient light during the day and emit a brilliant glow for hours in darkness, making it an invaluable resource for emergency lighting, decorative applications, and industrial safety markers.

Understanding the Science Behind Strontium Aluminate Technology

Chemical Composition and Crystal Structure

The fundamental chemistry of Strontium Aluminate Glow Powder involves a complex crystalline matrix of strontium aluminate doped with europium and dysprosium ions. This sophisticated chemical structure creates an efficient energy storage system that can capture photons from various light sources and release them gradually over extended periods. The europium ions serve as activators, determining the emission wavelength and color characteristics, while dysprosium acts as a co-activator, significantly enhancing the afterglow duration and intensity.

The crystal lattice structure of strontium aluminate provides numerous trap sites where excited electrons can be temporarily stored before recombining with holes to produce visible light. This mechanism allows the material to maintain luminescence for up to 12 hours or more after initial light exposure, representing a dramatic improvement over traditional phosphorescent materials. The stability of these trap sites at room temperature ensures consistent performance across various environmental conditions.

Photoluminescent Process and Energy Transfer

The photoluminescent process begins when Strontium Aluminate Glow Powder absorbs ultraviolet, visible, or infrared radiation from ambient light sources. During this charging phase, electrons within the crystal structure become excited and migrate to higher energy levels, where they remain trapped in metastable states. The efficiency of this energy absorption process directly correlates with the intensity and duration of the subsequent glow emission.

As thermal energy gradually provides sufficient activation energy, trapped electrons escape their capture sites and recombine with positive charges, releasing stored energy as visible photons. This controlled release mechanism explains why strontium aluminate materials can sustain brightness levels significantly longer than conventional glow-in-the-dark products. The wavelength of emitted light depends on the specific dopant concentrations and crystal field effects within the host lattice.

Applications and Industrial Uses

Safety and Emergency Systems

Emergency egress systems represent one of the most critical applications for Strontium Aluminate Glow Powder, where reliable illumination can mean the difference between safe evacuation and disaster. Building codes increasingly recognize photoluminescent materials as essential components of passive safety systems, particularly in high-rise structures, underground facilities, and marine environments where electrical power may fail during emergencies. These applications demand materials with proven longevity and brightness standards.

Fire departments and emergency responders utilize strontium aluminate markers for equipment identification, pathway marking, and personnel location tracking in smoke-filled environments. The material's ability to remain visible through dense smoke and maintain luminescence without battery power makes it invaluable for first responder safety protocols. Maritime applications include life jacket markers, lifeboat equipment, and deck safety striping that must perform reliably in harsh ocean conditions.

Decorative and Artistic Applications

Artists and designers have embraced Strontium Aluminate Glow Powder for creating stunning visual effects in sculptures, murals, and architectural features that transform spaces after dark. The material's superior brightness and color stability enable artistic works that maintain their impact throughout extended viewing periods. Interior designers incorporate these powders into flooring, wall treatments, and decorative elements that provide ambient lighting without electricity consumption.

Entertainment venues leverage strontium aluminate technology for stage effects, themed environments, and immersive experiences that captivate audiences. Theme parks utilize long-lasting glow effects for nighttime attractions, while concert venues create memorable lighting experiences that complement traditional electrical systems. The material's non-toxic nature and absence of radioactive components make it suitable for public spaces and family entertainment venues.

Manufacturing and Production Processes

Synthesis Methods and Quality Control

High-temperature solid-state reaction methods represent the primary manufacturing approach for producing premium Strontium Aluminate Glow Powder, requiring precise temperature control and atmospheric conditions to achieve optimal crystal formation. The synthesis process typically involves heating raw materials to temperatures exceeding 1300°C in controlled atmospheres, followed by carefully managed cooling cycles that promote proper crystal growth and dopant distribution.

Quality control measures throughout production ensure consistent particle size distribution, chemical purity, and luminescent performance characteristics. Advanced analytical techniques including X-ray diffraction, photoluminescence spectroscopy, and electron microscopy verify crystal structure integrity and identify potential defects that could compromise performance. Batch testing protocols evaluate glow intensity, decay time, and color consistency to maintain product specifications.

Particle Engineering and Surface Treatments

Particle size optimization plays a crucial role in determining the application characteristics of Strontium Aluminate Glow Powder, with different size distributions offering advantages for specific use cases. Fine particles provide smooth surface finishes in coatings and inks, while coarser grades deliver enhanced brightness for thick-film applications. Advanced milling and classification techniques ensure narrow size distributions that promote consistent dispersion in various carrier systems.

Surface modification treatments enhance compatibility with different binder systems and improve environmental stability. Specialized coating processes can provide moisture resistance, chemical stability, and improved adhesion properties that extend service life in demanding applications. These surface treatments maintain the luminescent properties while enabling integration into diverse manufacturing processes and end-use environments.

Performance Characteristics and Specifications

Brightness and Duration Metrics

The exceptional performance of Strontium Aluminate Glow Powder becomes evident through standardized brightness measurements that demonstrate luminance levels 10 to 20 times higher than traditional zinc sulfide materials. Initial brightness values can exceed 3000 mcd/m² immediately after light exposure, gradually decreasing to perceptible levels that remain visible for 8 to 12 hours under optimal conditions. These performance metrics establish strontium aluminate as the premier choice for applications requiring reliable long-duration illumination.

Decay curve analysis reveals the unique characteristics of strontium aluminate phosphorescence, showing rapid initial brightness followed by sustained intermediate levels and extended tail luminescence. This performance profile makes the material particularly suitable for safety applications where both immediate high visibility and long-term guidance are essential. Comparative testing demonstrates superior performance across various temperature ranges and environmental conditions.

Color Options and Spectral Properties

While yellow-green emission represents the most common and brightest option for Strontium Aluminate Glow Powder, advanced formulations provide alternative colors including blue, purple, and red variants to meet specific application requirements. The human eye's sensitivity to yellow-green wavelengths around 520 nanometers explains why this color appears brightest and most visible in low-light conditions, making it the preferred choice for safety applications.

Spectral stability ensures consistent color reproduction throughout the luminescent cycle, avoiding the color shifts commonly observed in inferior phosphorescent materials. Advanced dopant systems enable fine-tuning of emission wavelengths to match specific design requirements or coordinate with existing lighting schemes. Custom color formulations can be developed for specialized applications requiring unique spectral characteristics or enhanced performance in specific viewing conditions.

Integration Techniques and Application Methods

Coating and Paint Systems

Successful integration of Strontium Aluminate Glow Powder into coating systems requires careful consideration of particle loading levels, binder compatibility, and application techniques that preserve luminescent properties. Optimal particle concentrations typically range from 20% to 40% by weight, balancing glow intensity with coating integrity and workability. Specialized formulations accommodate various substrate types and environmental exposure conditions.

Professional application techniques ensure uniform distribution and maximum light exposure for charging purposes. Spray application methods provide excellent coverage for large surfaces, while brush and roller techniques offer precision control for detailed work. Surface preparation protocols remove contaminants and create optimal adhesion conditions that promote long-term performance and durability in exterior applications.

Plastics and Polymer Integration

Thermoplastic and thermoset polymer systems can incorporate Strontium Aluminate Glow Powder through various compounding and molding processes that maintain material properties while adding luminescent functionality. Injection molding parameters require adjustment to accommodate the ceramic filler and prevent degradation during high-temperature processing. Proper dispersion techniques ensure uniform distribution throughout the polymer matrix.

Extrusion processing enables continuous production of luminescent profiles, sheets, and films for diverse applications. Compatibility studies verify that strontium aluminate particles do not adversely affect polymer mechanical properties or processing characteristics. Specialized grades designed for polymer integration offer enhanced thermal stability and improved interfacial adhesion for demanding applications.

FAQ

How long does Strontium Aluminate Glow Powder maintain its luminescence after light exposure?

Strontium Aluminate Glow Powder typically maintains visible luminescence for 8 to 12 hours after adequate light exposure, with some high-performance grades continuing to emit detectable light for up to 20 hours. The actual duration depends on factors including initial charging intensity, ambient temperature, particle size, and specific formulation characteristics. Unlike traditional glow materials, strontium aluminate provides practical visibility levels throughout the night after just minutes of daylight or artificial light exposure.

What charging light sources work best for activating Strontium Aluminate Glow Powder?

While Strontium Aluminate Glow Powder responds to various light sources including natural sunlight, fluorescent lights, and LED illumination, ultraviolet and blue-rich light sources provide the most efficient charging. Direct sunlight offers optimal activation due to its broad spectrum and high intensity, requiring only 5-10 minutes for full charging. Indoor lighting typically requires 15-30 minutes for maximum charge, while specialized UV lamps can achieve full activation in just 1-2 minutes.

Is Strontium Aluminate Glow Powder safe for use in consumer products and food contact applications?

Strontium Aluminate Glow Powder is considered safe for most consumer applications as it contains no radioactive materials and does not emit harmful radiation. However, like other ceramic powders, it should not be ingested or inhaled in significant quantities. For food contact applications, the powder must be properly encapsulated within approved coating or polymer systems that prevent direct contact. Most commercial formulations meet safety standards for toys and consumer products when used according to manufacturer guidelines.

Can Strontium Aluminate Glow Powder be mixed with other phosphorescent materials to create custom colors?

While it is technically possible to blend different phosphorescent materials, mixing Strontium Aluminate Glow Powder with inferior materials typically reduces overall performance and may result in unpredictable color shifts during the luminescent cycle. For optimal results, custom colors should be achieved through specialized synthesis processes that maintain the superior characteristics of pure strontium aluminate systems. Professional suppliers can provide custom formulations that deliver specific color requirements while preserving maximum brightness and duration performance.

Table of Contents

- Understanding the Science Behind Strontium Aluminate Technology

- Applications and Industrial Uses

- Manufacturing and Production Processes

- Performance Characteristics and Specifications

- Integration Techniques and Application Methods

-

FAQ

- How long does Strontium Aluminate Glow Powder maintain its luminescence after light exposure?

- What charging light sources work best for activating Strontium Aluminate Glow Powder?

- Is Strontium Aluminate Glow Powder safe for use in consumer products and food contact applications?

- Can Strontium Aluminate Glow Powder be mixed with other phosphorescent materials to create custom colors?