Selecting the appropriate glow in the dark powder for your specific application requires understanding various factors that influence performance, durability, and overall effectiveness. Whether you're working on safety markings, decorative applications, or specialized industrial projects, the right phosphorescent material can make a significant difference in achieving your desired results. This comprehensive guide will help you navigate the selection process and make an informed decision based on your unique requirements.

Understanding Photoluminescent Technology

Basic Principles of Phosphorescence

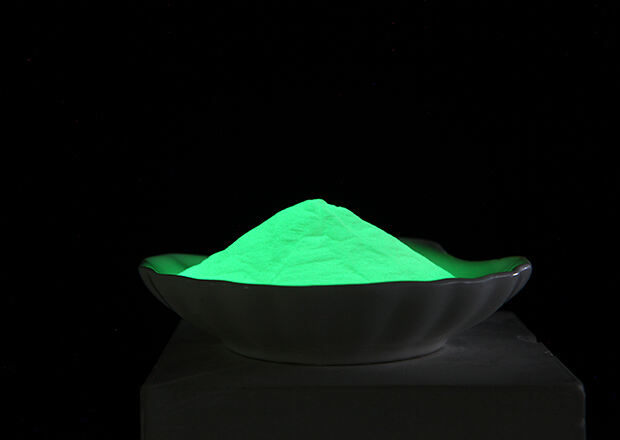

Photoluminescent materials work by absorbing light energy and slowly releasing it over time, creating the characteristic glow effect. When you expose glow in the dark powder to light sources, the photoluminescent particles store this energy and gradually emit it as visible light in darker conditions. This process, known as phosphorescence, can continue for hours depending on the quality and type of material used. The efficiency of this energy absorption and release cycle determines how bright and long-lasting your glow effect will be.

The most common photoluminescent compounds used in modern glow in the dark powder include strontium aluminate and zinc sulfide. Strontium aluminate-based powders typically offer superior brightness and longer glow duration compared to traditional zinc sulfide formulations. These advanced materials can maintain visible glow for up to twelve hours after initial light exposure, making them ideal for safety and emergency applications where reliability is crucial.

Color Variations and Their Applications

Different colors of glow in the dark powder serve specific purposes and offer varying levels of brightness and duration. Yellow-green variants typically provide the brightest and longest-lasting glow because human eyes are most sensitive to light in this wavelength range. Blue and aqua options offer unique aesthetic appeal but generally have shorter glow times and lower initial brightness levels.

Red, orange, and purple glow in the dark powder varieties create striking visual effects but require careful consideration of their performance characteristics. These colors often need stronger initial light charging and may not maintain their glow as long as yellow-green alternatives. Understanding these differences helps you select the most appropriate color for your specific application while managing expectations about performance levels.

Critical Selection Factors

Particle Size Considerations

The particle size of your chosen glow in the dark powder significantly impacts both application methods and final results. Finer particles, typically ranging from 10 to 50 microns, blend more easily with paints, resins, and other carrier mediums. These smaller particles create smoother finishes and work well in applications requiring precise detail or thin coatings.

Coarser particles, ranging from 75 to 200 microns, often provide brighter initial glow intensity due to their larger surface area for light absorption. However, these larger particles may create texture in your finished application and require compatible mixing techniques. Consider your application method, desired finish quality, and performance requirements when selecting the appropriate particle size range.

Brightness and Duration Requirements

Evaluating your brightness and duration needs helps narrow down suitable glow in the dark powder options. Safety applications typically require sustained visibility for extended periods, making high-performance strontium aluminate formulations the preferred choice. These materials maintain useful brightness levels for eight to twelve hours after proper light charging.

Decorative applications may prioritize initial brightness over extended duration, allowing for more flexibility in material selection. Consider the lighting conditions where your application will be used, the required visibility period, and any safety standards that must be met when determining appropriate brightness and duration specifications.

Application-Specific Considerations

Environmental Durability Requirements

Outdoor applications demand glow in the dark powder with enhanced weather resistance and UV stability. Extended exposure to sunlight can degrade some photoluminescent materials, reducing their effectiveness over time. Look for powders specifically formulated for outdoor use, which often include protective coatings or stabilizing additives to maintain performance in challenging conditions.

Indoor applications generally face fewer environmental challenges but may still require consideration of factors like humidity, temperature fluctuations, and chemical exposure. Industrial environments may present additional challenges such as oil, solvents, or abrasive conditions that could affect the longevity of your glow in the dark powder application.

Carrier Medium Compatibility

The compatibility between your selected glow in the dark powder and intended carrier medium directly affects application success and final performance. Water-based paints, solvent-based coatings, epoxy resins, and silicone materials each present different compatibility considerations that must be addressed during selection.

Some glow in the dark powder formulations include surface treatments that improve dispersion and reduce settling in liquid carriers. These treated powders often justify their higher cost through improved workability and more consistent results. Test compatibility with small batches before committing to large-scale applications to ensure optimal performance and avoid costly application failures.

Performance Optimization Strategies

Proper Loading Concentrations

Achieving optimal performance from your glow in the dark powder requires understanding appropriate loading concentrations for your specific application. Higher concentrations generally produce brighter glow effects but may impact the mechanical properties of your carrier medium. Most applications work well with concentrations between 15% and 30% by weight, though some specialized uses may require different ratios.

Excessive loading can lead to poor adhesion, reduced durability, and increased material costs without proportional performance gains. Insufficient loading results in weak glow effects that may not meet your visibility requirements. Conduct small-scale testing to determine the optimal concentration that balances performance, cost, and application characteristics for your specific needs.

Light Charging Optimization

Maximizing the performance of glow in the dark powder requires understanding proper light charging techniques. The intensity, duration, and spectrum of charging light all influence the resulting glow performance. Natural sunlight provides excellent charging, but artificial light sources can also effectively energize photoluminescent materials when properly applied.

LED lights, fluorescent fixtures, and halogen sources each offer different charging characteristics that affect how well your glow in the dark powder performs. Consider the available light sources in your application environment and plan accordingly to ensure adequate charging opportunities. Some applications may benefit from dedicated charging lights to maintain optimal performance levels.

Quality Assessment and Testing

Standardized Performance Metrics

Professional-grade glow in the dark powder should come with standardized performance data including initial brightness measurements, decay curves, and afterglow duration specifications. These metrics, typically measured in millicandelas per square meter, allow objective comparison between different products and suppliers. Understanding these specifications helps ensure your selected material meets project requirements.

Look for products tested according to recognized standards such as DIN 67510 or ASTM E2072, which provide standardized testing protocols for photoluminescent materials. These standards ensure consistent measurement methods and reliable performance data that you can use to make informed selection decisions and verify product quality upon receipt.

Sample Testing Procedures

Before committing to large quantities of glow in the dark powder, conduct thorough sample testing under conditions that simulate your intended application. Prepare test samples using your planned mixing ratios, application methods, and substrate materials to evaluate real-world performance characteristics.

Document charging times, initial brightness, glow duration, and any application challenges encountered during testing. This information proves invaluable for optimizing your process and avoiding potential issues during full-scale implementation. Consider testing multiple products to identify the best performer for your specific requirements and budget constraints.

Cost-Benefit Analysis

Initial Investment vs Long-Term Value

While high-quality glow in the dark powder may require a larger initial investment, superior performance characteristics often justify the additional cost through extended service life and better functionality. Premium strontium aluminate formulations typically last longer, glow brighter, and maintain consistent performance over time compared to lower-cost alternatives.

Consider factors beyond initial material cost, including application ease, maintenance requirements, and replacement frequency when evaluating options. A slightly more expensive glow in the dark powder that performs reliably for years may prove more economical than frequent replacement of cheaper alternatives that degrade quickly or fail to meet performance expectations.

Application Volume Considerations

Large-scale applications may benefit from bulk purchasing options that reduce per-unit costs while ensuring consistent material properties across your entire project. Many suppliers offer volume discounts and custom packaging options that can significantly impact project economics for substantial installations.

Small-scale or prototype applications might justify premium materials that offer superior performance even at higher per-unit costs. The ability to achieve desired results with minimal material waste and application challenges often outweighs cost savings from lower-grade alternatives in these scenarios.

FAQ

How long does glow in the dark powder maintain its luminescent properties

High-quality strontium aluminate glow in the dark powder can maintain its photoluminescent properties for over 20 years when properly applied and protected from environmental degradation. The actual service life depends on factors including UV exposure, temperature cycling, chemical contact, and mechanical wear. Indoor applications typically last longer than outdoor installations due to reduced environmental stress.

Can different colors of glow in the dark powder be mixed together

Yes, different colored glow in the dark powder varieties can be mixed to create custom color effects, though the resulting glow characteristics may differ from individual colors. Yellow-green typically dominates mixed combinations due to its superior brightness and efficiency. Test small batches to evaluate the final color and performance before large-scale mixing, as some combinations may produce unexpected results or reduced overall brightness.

What safety considerations apply when working with glow in the dark powder

Modern glow in the dark powder formulations are generally non-toxic and safe for normal handling, but basic safety precautions should be followed during application. Wear appropriate respiratory protection to avoid inhaling fine particles, use gloves to prevent skin contact, and ensure adequate ventilation in work areas. Always consult material safety data sheets for specific handling requirements and disposal guidelines for your chosen product.

How does temperature affect glow in the dark powder performance

Temperature variations can impact both the charging efficiency and glow output of glow in the dark powder applications. Higher temperatures during charging generally improve energy absorption, while extremely cold conditions may reduce glow brightness and duration. Most quality formulations perform reliably across normal temperature ranges, but extreme conditions may require specialized materials designed for challenging thermal environments.