Modern manufacturing industries increasingly prioritize worker safety and environmental responsibility, making photoluminescent pigments a critical component in numerous applications. These innovative materials offer exceptional glow-in-the-dark properties without compromising safety standards or introducing toxic substances into the workplace. Understanding the benefits and applications of photoluminescent pigments helps manufacturers make informed decisions about incorporating these materials into their production processes.

The evolution of photoluminescent pigments has transformed safety signage, emergency exit systems, and industrial marking applications across diverse sectors. Contemporary formulations eliminate harmful radioactive materials that characterized earlier luminescent technologies, replacing them with safe alkaline earth aluminates and zinc sulfide compounds. This advancement ensures that photoluminescent pigments meet stringent safety regulations while delivering superior performance characteristics that exceed traditional alternatives.

Understanding Photoluminescent Pigment Technology

Chemical Composition and Safety Profile

Modern photoluminescent pigments utilize strontium aluminate and zinc sulfide as primary active compounds, completely eliminating radioactive materials previously used in legacy formulations. These non-toxic ingredients absorb ambient light energy during exposure and release it slowly through phosphorescence, creating sustained illumination without electrical power requirements. The chemical stability of these compounds ensures that photoluminescent pigments remain safe throughout their operational lifespan, even under extreme temperature variations and mechanical stress conditions.

Manufacturers subject photoluminescent pigments to rigorous testing protocols that verify compliance with international safety standards including ASTM E2072 and DIN 67510. These comprehensive evaluations assess toxicity levels, skin irritation potential, and environmental impact to guarantee that products meet or exceed regulatory requirements. Independent laboratory analyses consistently demonstrate that contemporary photoluminescent pigments pose no health risks during normal handling, processing, or end-use applications.

Performance Characteristics and Durability

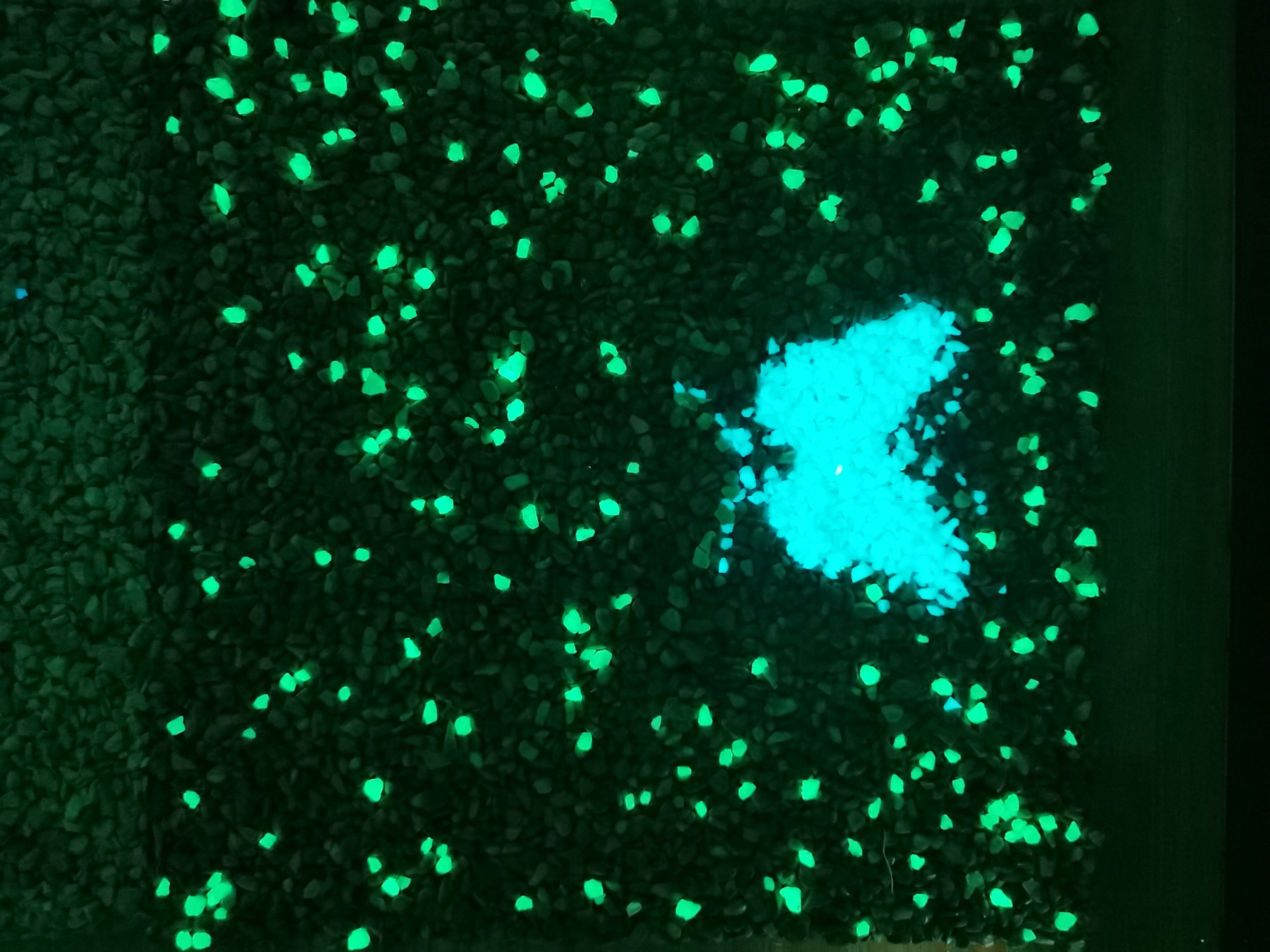

High-quality photoluminescent pigments exhibit exceptional brightness levels immediately following light exposure, with afterglow duration extending up to twelve hours depending on the specific formulation and charging conditions. The photoluminescent efficiency of these materials surpasses conventional alternatives by significant margins, providing reliable visibility in emergency situations when conventional lighting systems fail. Advanced manufacturing techniques ensure consistent particle size distribution and optimal crystal structure formation that maximizes light absorption and emission capabilities.

Temperature resistance represents another crucial advantage of modern photoluminescent pigments, with premium grades maintaining functionality across temperature ranges from negative forty to positive one hundred fifty degrees Celsius. This thermal stability enables applications in harsh industrial environments where traditional luminescent materials would degrade rapidly. The inherent durability of photoluminescent pigments translates to extended service life and reduced maintenance requirements compared to battery-powered or electrically-illuminated alternatives.

Industrial Applications and Safety Benefits

Emergency Egress and Safety Signage

Emergency exit systems incorporating photoluminescent pigments provide critical visibility during power outages, fires, or other emergency situations when conventional lighting becomes unavailable. These materials charge continuously under normal lighting conditions and activate automatically when ambient illumination decreases, eliminating the need for battery backup systems or electrical connections. Safety professionals recognize that photoluminescent pigments offer superior reliability compared to electrically-powered emergency lighting systems that may fail during critical moments.

Building codes and safety regulations increasingly mandate the use of photoluminescent materials in high-rise structures, industrial facilities, and public buildings to enhance occupant safety during emergency evacuations. The consistent performance of photoluminescent pigments under diverse environmental conditions makes them ideal for marking stairwells, corridors, and exit routes that must remain visible regardless of external circumstances. Integration of these materials into architectural elements creates comprehensive wayfinding systems that guide occupants safely to building exits without relying on vulnerable electrical infrastructure.

Industrial Marking and Identification

Manufacturing facilities utilize photoluminescent pigments for marking hazardous areas, equipment controls, and critical infrastructure components that require visibility during low-light conditions or power failures. These applications enhance workplace safety by ensuring that essential markings remain visible when workers need them most, particularly during maintenance activities or emergency response procedures. The non-toxic nature of modern photoluminescent pigments eliminates concerns about worker exposure during routine handling and application processes.

Offshore platforms, mining operations, and chemical processing facilities benefit significantly from photoluminescent marking systems that function independently of electrical power supplies. The harsh environmental conditions common in these industries demand robust materials that maintain performance over extended periods without degradation. Photoluminescent pigments meet these demanding requirements while providing cost-effective solutions that reduce long-term maintenance expenses and improve overall safety outcomes.

Environmental Impact and Sustainability

Eco-Friendly Manufacturing Processes

The production of contemporary photoluminescent pigments employs environmentally responsible manufacturing techniques that minimize waste generation and eliminate harmful emissions associated with traditional luminescent materials. Raw material sourcing emphasizes sustainable practices and responsible extraction methods that reduce environmental impact throughout the supply chain. Quality control procedures ensure that finished photoluminescent pigments contain no heavy metals, radioactive substances, or other environmentally hazardous compounds that could compromise ecological systems.

Lifecycle assessments demonstrate that photoluminescent pigments offer significant environmental advantages compared to electrically-powered alternatives, particularly regarding energy consumption and carbon footprint reduction. The passive operation of these materials eliminates ongoing electrical power requirements, contributing to reduced greenhouse gas emissions and lower operational costs over the product lifespan. Disposal considerations favor photoluminescent pigments because they contain no hazardous materials requiring special handling or treatment protocols.

Regulatory Compliance and Certification

International regulatory agencies including the Environmental Protection Agency and European Chemicals Agency have evaluated photoluminescent pigments extensively and confirmed their safety for commercial and industrial applications. Comprehensive toxicological studies demonstrate that these materials pose no significant health risks to workers, consumers, or environmental systems when used according to established guidelines. Certification programs verify that photoluminescent pigments meet or exceed safety standards established by relevant regulatory authorities.

Quality assurance protocols ensure that photoluminescent pigments undergo continuous monitoring throughout the manufacturing process to maintain consistency and safety standards. Third-party testing laboratories provide independent verification of product specifications and safety characteristics, offering additional assurance to end users regarding material performance and safety profiles. These rigorous oversight mechanisms guarantee that photoluminescent pigments delivered to customers meet the highest standards for safety, performance, and environmental responsibility.

Application Techniques and Best Practices

Surface Preparation and Application Methods

Successful implementation of photoluminescent pigments requires careful attention to surface preparation techniques that ensure optimal adhesion and performance characteristics. Clean, dry surfaces free from contaminants provide the foundation for durable applications that maintain effectiveness throughout the intended service life. Professional applicators recommend specific primer systems and surface treatments that enhance the bonding between photoluminescent coatings and substrate materials.

Application techniques vary depending on the specific formulation of photoluminescent pigments and the intended end use requirements. Spray application methods offer excellent coverage uniformity and efficient material utilization for large-scale projects, while brush or roller techniques provide precise control for detailed marking applications. Temperature and humidity conditions during application significantly influence curing characteristics and final performance properties of photoluminescent systems.

Quality Control and Performance Verification

Post-application testing procedures verify that photoluminescent pigments achieve specified brightness levels and duration requirements under actual operating conditions. Calibrated photometers measure luminance values at predetermined intervals following light exposure to confirm compliance with performance specifications. Documentation of test results provides objective evidence of system performance and supports maintenance planning activities.

Regular maintenance inspections ensure that photoluminescent pigments continue delivering optimal performance throughout their operational lifespan. Visual assessments identify areas requiring attention due to mechanical damage, contamination, or normal wear patterns that could compromise visibility effectiveness. Proactive maintenance approaches maximize the service life of photoluminescent systems while ensuring consistent safety performance under all operating conditions.

Cost-Effectiveness and Return on Investment

Initial Investment Considerations

The upfront cost of photoluminescent pigments compares favorably to electrically-powered alternatives when considering the total system requirements including wiring, electrical components, and installation labor. Elimination of electrical infrastructure reduces complexity and installation costs while improving system reliability through the removal of potential failure points. Budget planning benefits from the predictable costs associated with photoluminescent systems that do not require ongoing electrical power consumption or battery replacement expenses.

Material costs for high-quality photoluminescent pigments reflect the advanced technology and manufacturing processes required to achieve superior performance characteristics. However, the extended service life and minimal maintenance requirements of these materials provide excellent value propositions compared to alternatives requiring frequent component replacement or electrical system maintenance. Cost analysis should consider the total lifecycle expenses rather than focusing exclusively on initial material procurement costs.

Long-term Operational Savings

Operational cost advantages of photoluminescent pigments include elimination of electricity consumption, reduced maintenance requirements, and extended service intervals that minimize disruption to normal operations. The passive nature of these materials eliminates concerns about power failures, electrical faults, or component degradation that plague traditional lighting systems. Insurance considerations may favor facilities utilizing photoluminescent safety systems due to their enhanced reliability and reduced fire risk compared to electrical alternatives.

Maintenance cost reductions result from the inherent durability and stability of modern photoluminescent pigments that require minimal attention throughout their operational lifespan. Cleaning procedures typically involve simple washing with mild detergents, eliminating the need for specialized maintenance equipment or technical expertise. The absence of moving parts, electrical connections, or replaceable components further reduces ongoing operational expenses while improving system reliability and availability.

FAQ

Are photoluminescent pigments safe for workers to handle during application?

Yes, modern photoluminescent pigments are completely safe for workers to handle when proper safety protocols are followed. These materials contain no radioactive substances, heavy metals, or toxic compounds that could pose health risks. Standard personal protective equipment including gloves, eye protection, and dust masks provides adequate protection during mixing and application procedures. Material safety data sheets provide comprehensive handling guidelines and emergency response information.

How long do photoluminescent pigments maintain their glow properties?

High-quality photoluminescent pigments can maintain visible glow for up to twelve hours after light exposure, with the brightest illumination occurring during the first few hours following charging. The duration and intensity depend on factors including the specific formulation, charging time, light source intensity, and environmental conditions. Premium formulations designed for critical safety applications typically provide reliable visibility for eight to ten hours under normal operating conditions.

What maintenance is required for photoluminescent pigment applications?

Maintenance requirements for photoluminescent pigments are minimal compared to electrically-powered alternatives. Regular cleaning with mild soap and water removes accumulated dirt or contaminants that could reduce light absorption efficiency. Visual inspections should identify areas requiring touch-up due to mechanical damage or normal wear. Most installations require only periodic cleaning and occasional minor repairs to maintain optimal performance throughout their service life.

Can photoluminescent pigments be used in extreme temperature environments?

Yes, premium photoluminescent pigments are engineered to function effectively across wide temperature ranges typically from negative forty to positive one hundred fifty degrees Celsius. Specialized formulations designed for extreme environments can extend these operating ranges further while maintaining consistent performance characteristics. Temperature cycling tests verify that these materials retain their luminescent properties and structural integrity under harsh environmental conditions common in industrial applications.