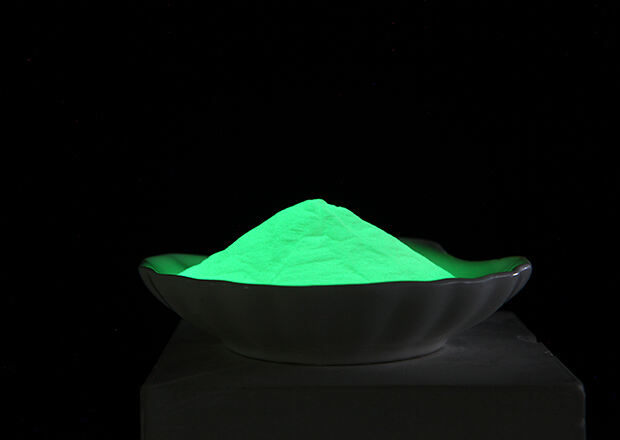

Luminescent materials have revolutionized countless industries, from safety applications to entertainment products. Among the most significant developments in this field is the evolution of glow powder technology, which has transformed how we think about photoluminescent materials. Understanding the fundamental differences between traditional zinc sulfide and modern strontium aluminate formulations is crucial for manufacturers, engineers, and product developers seeking optimal performance in their applications.

The photoluminescent industry has witnessed remarkable technological advancements over the past several decades. These innovations have led to the development of superior glow powder compositions that offer enhanced brightness, extended duration, and improved stability. Modern manufacturing processes now enable the production of highly refined phosphorescent materials that meet stringent quality standards across various commercial and industrial sectors.

Chemical Composition and Structure

Strontium Aluminate Foundation

Strontium aluminate represents the pinnacle of modern glow powder technology, featuring a sophisticated crystalline structure that enables exceptional light absorption and emission properties. The base compound, typically SrAl2O4, is enhanced with specific rare earth dopants such as europium and dysprosium to achieve optimal performance characteristics. This advanced chemical composition allows strontium aluminate materials to achieve brightness levels that are significantly superior to traditional alternatives.

The crystalline lattice structure of strontium aluminate provides numerous trap sites for excited electrons, enabling extended energy storage and gradual photon release. This unique arrangement results in glow powder that can maintain visible luminescence for hours after initial excitation. The material's stability under various environmental conditions makes it particularly suitable for demanding applications where consistent performance is essential.

Zinc Sulfide Characteristics

Traditional zinc sulfide formulations have served as the foundation of phosphorescent technology for many decades. These materials typically consist of ZnS crystals activated with copper or silver dopants to produce characteristic emission wavelengths. While zinc sulfide glow powder has been widely used in numerous applications, its performance characteristics are generally limited compared to modern alternatives.

The structure of zinc sulfide allows for rapid light absorption and emission, but the energy storage capacity is relatively modest. This limitation results in shorter afterglow duration and reduced brightness intensity over time. Despite these constraints, zinc sulfide materials remain cost-effective solutions for specific applications where extended luminescence duration is not a primary requirement.

Performance Characteristics

Brightness and Intensity

The luminous intensity of strontium aluminate glow powder significantly exceeds that of zinc sulfide materials, often achieving brightness levels that are 10 to 20 times greater during initial afterglow periods. This enhanced performance stems from the superior energy absorption efficiency and optimized crystal structure that enables more effective photon generation. Industrial testing consistently demonstrates that strontium aluminate formulations maintain higher visibility levels under various lighting conditions.

Peak brightness measurements reveal that high-quality strontium aluminate materials can achieve initial intensities exceeding 300 millicandela per square meter, while traditional zinc sulfide typically reaches maximum values of 20 to 30 millicandela per square meter. This substantial difference in luminous output directly impacts the effectiveness of safety applications, emergency signage, and decorative products where visibility is paramount.

Duration and Persistence

Extended afterglow duration represents one of the most significant advantages of modern strontium aluminate glow powder technology. Premium formulations can maintain visible luminescence for 8 to 12 hours after excitation, with some specialized compositions extending this period even further. The gradual decay curve of strontium aluminate ensures consistent light emission throughout the afterglow period.

Zinc sulfide materials typically provide visible afterglow for 30 minutes to 2 hours depending on the specific formulation and excitation intensity. While this shorter duration may be adequate for certain applications, the extended performance of strontium aluminate makes it the preferred choice for critical safety systems and long-term visibility requirements. The persistence characteristics directly influence product design considerations and application suitability.

Manufacturing and Processing

Production Methods

Modern strontium aluminate glow powder production involves sophisticated high-temperature synthesis processes that require precise control of atmospheric conditions and raw material purity. The manufacturing sequence typically includes multiple firing stages at temperatures exceeding 1400°C, followed by controlled cooling and particle size optimization. These demanding production requirements contribute to higher manufacturing costs but ensure superior performance characteristics.

Quality control measures during strontium aluminate production include spectral analysis, particle distribution testing, and luminescence performance validation. Each batch undergoes comprehensive evaluation to ensure consistency and adherence to specified performance standards. The complexity of the manufacturing process necessitates specialized equipment and expertise, limiting production to established facilities with appropriate technical capabilities.

Processing Considerations

Zinc sulfide glow powder manufacturing follows relatively straightforward precipitation and thermal treatment processes that can be accomplished at lower temperatures and with less sophisticated equipment. This simplified production approach results in lower manufacturing costs and greater accessibility for various suppliers. However, the reduced complexity may also contribute to wider performance variations between different sources and batches.

The processing requirements for both materials influence their integration into finished products. Strontium aluminate powders often require specialized handling procedures to maintain optimal performance characteristics, while zinc sulfide materials are generally more tolerant of standard industrial processing methods. These considerations affect product development timelines and manufacturing complexity.

Application Areas and Uses

Safety and Emergency Systems

Emergency egress systems represent one of the most critical applications for high-performance glow powder materials. Strontium aluminate formulations are increasingly specified for exit signs, pathway marking, and safety equipment where extended visibility duration is essential for occupant safety. The superior brightness and duration characteristics of these materials ensure effective guidance during power outages and emergency conditions.

Building codes and safety regulations in many jurisdictions now recognize the advantages of strontium aluminate-based systems, leading to increased adoption in commercial and residential construction projects. The reliability and performance consistency of modern photoluminescent materials contribute to enhanced life safety systems that function effectively without electrical power or maintenance requirements.

Commercial and Industrial Applications

The versatility of glow powder technology extends across numerous commercial and industrial sectors, including textile manufacturing, plastics production, and specialty coatings. Strontium aluminate materials enable the development of innovative products that combine functional performance with aesthetic appeal. Applications range from decorative elements to functional safety components that enhance product value and user experience.

Industrial applications often require materials that can withstand challenging environmental conditions while maintaining consistent performance over extended periods. The chemical stability and durability of strontium aluminate formulations make them suitable for outdoor applications, marine environments, and high-temperature conditions where traditional materials may degrade or lose effectiveness.

Cost Analysis and Economic Factors

Initial Investment Considerations

The cost differential between strontium aluminate and zinc sulfide glow powder materials reflects the complexity of their respective manufacturing processes and raw material requirements. Strontium aluminate formulations typically command premium pricing due to the sophisticated production methods and rare earth dopant materials required for optimal performance. However, this higher initial cost must be evaluated against the enhanced performance benefits and potential long-term value.

Economic analysis should consider the total cost of ownership, including product longevity, maintenance requirements, and replacement frequency. While strontium aluminate materials involve higher upfront costs, their superior performance characteristics may result in lower lifetime costs for applications where extended duration and brightness are critical factors.

Market Trends and Pricing

Market dynamics in the photoluminescent materials industry continue to evolve as manufacturing technologies improve and production volumes increase. The growing demand for high-performance glow powder materials has led to increased competition among suppliers and gradual price reductions for premium formulations. These market trends make advanced materials more accessible for a broader range of applications.

Supply chain considerations also influence pricing structures, particularly for materials that depend on rare earth elements or specialized processing capabilities. Understanding these market factors helps product developers make informed decisions about material selection and supplier relationships for their specific applications and performance requirements.

Environmental and Safety Considerations

Environmental Impact

Environmental sustainability has become an increasingly important factor in material selection decisions across all industries. Strontium aluminate glow powder formulations are generally considered environmentally friendly, as they do not contain radioactive materials or heavy metals that could pose disposal challenges. The inorganic nature of these materials ensures stability under normal environmental conditions without degradation into harmful byproducts.

Lifecycle assessment studies indicate that the environmental impact of photoluminescent materials is minimal when properly manufactured and disposed of according to established guidelines. The energy-free operation of these materials during their functional lifetime contributes to reduced environmental impact compared to electrically powered alternatives.

Health and Safety Protocols

Workplace safety protocols for handling glow powder materials focus primarily on preventing inhalation of fine particles during processing and application procedures. Both strontium aluminate and zinc sulfide formulations require appropriate dust control measures and personal protective equipment to ensure worker safety. Material safety data sheets provide comprehensive guidance for safe handling, storage, and disposal procedures.

The non-toxic nature of properly formulated photoluminescent materials makes them suitable for consumer products and applications where human contact may occur. Regulatory compliance with relevant safety standards ensures that finished products meet established requirements for consumer safety and product liability considerations.

FAQ

What is the main difference between strontium aluminate and zinc sulfide glow powder

The primary difference lies in performance characteristics, with strontium aluminate offering significantly brighter luminescence and extended afterglow duration compared to zinc sulfide. Strontium aluminate can maintain visible light for 8-12 hours while zinc sulfide typically lasts 30 minutes to 2 hours. Additionally, strontium aluminate achieves brightness levels 10-20 times greater than zinc sulfide materials, making it superior for applications requiring extended visibility and high intensity.

How do manufacturing costs compare between these two glow powder types

Strontium aluminate manufacturing involves more complex processes and expensive rare earth materials, resulting in higher production costs compared to zinc sulfide. However, the superior performance characteristics of strontium aluminate often justify the premium pricing for applications where extended duration and brightness are critical. The total cost of ownership analysis should consider performance benefits alongside initial material costs to determine the most economical solution for specific applications.

Which material is better for safety and emergency applications

Strontium aluminate is generally preferred for safety and emergency applications due to its extended afterglow duration and superior brightness characteristics. These properties ensure reliable visibility during power outages and emergency conditions when occupant safety depends on effective photoluminescent guidance systems. Many building codes and safety regulations now recognize the advantages of strontium aluminate-based emergency egress systems over traditional zinc sulfide alternatives.

Are there environmental concerns with either glow powder material

Both strontium aluminate and zinc sulfide glow powder formulations are considered environmentally safe when properly manufactured and handled. These materials do not contain radioactive substances or heavy metals that pose significant disposal challenges. The inorganic nature of both materials ensures stability under normal environmental conditions, and their energy-free operation during functional lifetime contributes to reduced environmental impact compared to electrically powered lighting alternatives.