Industrial applications requiring long-lasting luminescent properties rely heavily on strontium aluminate glow powder, a revolutionary phosphorescent material that has transformed various manufacturing sectors. This advanced compound offers superior performance compared to traditional zinc sulfide alternatives, providing extended afterglow duration and enhanced brightness characteristics. Understanding where to source quality strontium aluminate glow powder becomes crucial for businesses seeking reliable suppliers and consistent product specifications. The market for these specialized materials continues expanding as industries recognize the value of sustainable, non-radioactive luminescent solutions for diverse applications ranging from safety signage to decorative elements.

Understanding Strontium Aluminate Technology and Benefits

Chemical Composition and Properties

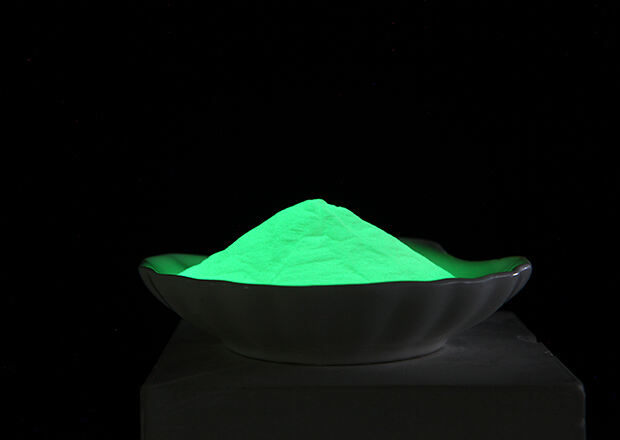

The molecular structure of strontium aluminate glow powder consists primarily of strontium aluminate doped with rare earth elements, particularly europium and dysprosium. These dopants serve as activation centers that enable the material to absorb and store light energy efficiently. The crystalline structure allows for optimal photon capture during the charging phase, while the rare earth elements facilitate the controlled release of stored energy over extended periods. This sophisticated composition results in afterglow durations that can exceed twelve hours under optimal conditions, significantly outperforming conventional phosphorescent materials.

Temperature stability represents another critical advantage of strontium aluminate glow powder, maintaining consistent luminescent properties across a broad temperature range. The material demonstrates remarkable resistance to thermal degradation, ensuring reliable performance in both indoor and outdoor applications. Chemical inertness prevents unwanted reactions with common binding agents and substrates, making it compatible with various manufacturing processes and end-use environments.

Performance Advantages Over Traditional Alternatives

Brightness intensity measurements consistently show that strontium aluminate glow powder delivers luminosity levels ten times greater than zinc sulfide-based alternatives. This enhanced brightness proves particularly valuable in safety applications where visibility remains paramount during emergency situations. The initial brightness upon activation reaches impressive levels, while the sustained glow maintains adequate visibility for practical applications throughout the night cycle.

Environmental safety considerations strongly favor strontium aluminate glow powder due to its non-toxic and non-radioactive nature. Unlike radium-based luminescent materials historically used in various applications, modern strontium aluminate compounds pose no health risks to manufacturers or end users. This safety profile enables broader application possibilities and simplified handling procedures during production and installation processes.

Key Sourcing Considerations for Industrial Buyers

Quality Standards and Certifications

Establishing quality benchmarks becomes essential when evaluating potential suppliers of strontium aluminate glow powder, as performance variations significantly impact end-product reliability. International standards organizations have developed testing protocols that assess brightness levels, afterglow duration, particle size distribution, and chemical purity. Reputable suppliers provide comprehensive technical data sheets documenting these parameters alongside independent laboratory test results that verify claimed performance characteristics.

Manufacturing certifications such as ISO 9001 quality management systems indicate supplier commitment to consistent production processes and quality control measures. Environmental management certifications demonstrate responsible manufacturing practices, particularly important given the specialized nature of rare earth element processing. Suppliers maintaining these certifications typically implement rigorous batch testing procedures that ensure each shipment meets specified performance criteria.

Supply Chain Reliability and Capacity

Production capacity assessment helps determine whether potential suppliers can meet both current requirements and future scaling needs for strontium aluminate glow powder procurement. Established manufacturers typically maintain multiple production lines with redundancy measures that minimize supply disruption risks. Geographic diversity in supplier selection provides additional security against regional disruptions while potentially offering logistical advantages depending on facility locations.

Raw material sourcing transparency becomes increasingly important as rare earth element markets experience periodic volatility. Suppliers with direct relationships to mining operations or established long-term contracts demonstrate greater supply chain stability. Forward integration strategies employed by leading suppliers often include strategic raw material inventory management that buffers against market fluctuations and ensures consistent product availability.

Evaluating Supplier Capabilities and Technical Support

Manufacturing Expertise and Technology

Advanced production technologies distinguish leading suppliers of strontium aluminate glow powder from commodity manufacturers, directly impacting product consistency and performance characteristics. State-of-the-art synthesis equipment enables precise control over particle size distribution, crystal structure formation, and dopant incorporation levels. Automated quality control systems continuously monitor production parameters, ensuring each batch meets stringent specifications before packaging and shipment.

Research and development capabilities indicate supplier commitment to continuous improvement and innovation in strontium aluminate glow powder technology. Companies investing in proprietary formulations often achieve superior performance characteristics through optimized dopant ratios and enhanced synthesis techniques. Collaborative development programs allow customers to work directly with supplier technical teams to customize products for specific application requirements.

Technical Documentation and Application Support

Comprehensive technical support services differentiate professional suppliers from basic commodity providers, offering valuable assistance throughout the product selection and implementation process. Detailed application guides provide specific recommendations for incorporation techniques, mixing ratios, and processing parameters optimized for different end uses. Material safety data sheets and regulatory compliance documentation ensure safe handling procedures and facilitate regulatory approval processes.

Custom formulation capabilities enable suppliers to modify strontium aluminate glow powder characteristics to meet specific application requirements, including particle size optimization, color tuning, and performance enhancement. Technical consultation services help customers optimize processing parameters and troubleshoot integration challenges, maximizing the effectiveness of the luminescent material in final applications.

Cost Analysis and Value Optimization

Pricing Structure Understanding

Market pricing for strontium aluminate glow powder reflects the complex manufacturing processes and specialized raw materials required for production. Volume-based pricing tiers typically offer significant cost advantages for larger quantity purchases, making bulk procurement strategies financially attractive for regular users. Price volatility factors include rare earth element market fluctuations, energy costs associated with high-temperature synthesis processes, and regulatory compliance expenses that suppliers must absorb.

Total cost of ownership calculations should incorporate not only initial purchase prices but also transportation costs, storage requirements, and waste minimization benefits associated with high-performance strontium aluminate glow powder. Superior brightness and duration characteristics often justify premium pricing through reduced material consumption and enhanced end-product performance that commands higher market values.

Long-term Value Considerations

Partnership benefits extend beyond simple supplier relationships when working with established strontium aluminate glow powder manufacturers, often including preferential pricing, priority allocation during supply constraints, and collaborative development opportunities. Long-term supply agreements provide price stability and guaranteed availability, particularly valuable in markets where demand growth exceeds production capacity expansion rates.

Innovation access through supplier partnerships enables early adoption of next-generation strontium aluminate glow powder formulations and manufacturing techniques. Leading suppliers often share technology roadmaps with strategic customers, providing insights into future performance improvements and new application possibilities that support competitive advantage development.

Regional Supplier Landscape and Selection Criteria

Global Manufacturing Centers

Asia-Pacific regions dominate global strontium aluminate glow powder production due to proximity to rare earth mining operations and established chemical processing infrastructure. Chinese manufacturers lead production capacity with several large-scale facilities specializing in phosphorescent materials, while Japanese companies focus on high-end applications requiring superior quality specifications. European producers typically serve specialized markets with premium products and extensive technical support services.

North American production capacity remains limited but growing, with several companies establishing local manufacturing to serve regional markets and reduce supply chain dependencies. Transportation costs and lead times favor regional suppliers for bulk applications, while specialized formulations may justify international sourcing from centers of excellence regardless of geographic location.

Supplier Evaluation Methodology

Systematic supplier assessment begins with comprehensive capability audits that evaluate production capacity, quality systems, technical expertise, and financial stability. Site visits provide direct observation of manufacturing processes, quality control procedures, and inventory management systems that impact product consistency and delivery reliability. Reference checks with existing customers offer insights into supplier performance under various business conditions and market cycles.

Performance metrics establishment creates objective evaluation criteria for ongoing supplier relationship management, including quality scores, delivery performance, technical support responsiveness, and innovation contributions. Regular supplier reviews ensure continued alignment with evolving requirements and identify opportunities for relationship enhancement or strategic adjustments based on changing market conditions.

Application-Specific Sourcing Strategies

Safety and Emergency Applications

Emergency egress systems require strontium aluminate glow powder with exceptional brightness and extended duration characteristics to ensure visibility during power outages and emergency situations. Regulatory compliance for safety applications often mandates specific performance standards and certification requirements that limit supplier options to qualified manufacturers with appropriate testing capabilities and documentation systems.

Marine and aerospace applications demand additional performance criteria including resistance to moisture, temperature extremes, and vibration exposure that challenge standard formulations. Specialized grades of strontium aluminate glow powder designed for harsh environments typically require custom synthesis parameters and enhanced quality control measures that justify premium pricing structures.

Consumer and Decorative Markets

Decorative applications emphasize color variety and aesthetic appeal over maximum performance, creating opportunities for cost optimization through tailored formulations of strontium aluminate glow powder. Consumer markets often prioritize consistent appearance and reasonable pricing over ultimate performance characteristics, enabling suppliers to offer value-engineered products that meet market requirements efficiently.

Packaging and presentation requirements for consumer markets differ significantly from industrial applications, with smaller quantities, attractive labeling, and user-friendly handling characteristics becoming important selection criteria. Suppliers serving both industrial and consumer markets typically offer different packaging options and technical support levels appropriate for each market segment.

Future Trends and Market Evolution

Technology Development Directions

Ongoing research in strontium aluminate glow powder focuses on extending afterglow duration, enhancing brightness levels, and developing new color options beyond traditional green emissions. Advanced synthesis techniques including sol-gel processing and microwave-assisted synthesis promise improved particle uniformity and performance consistency. Nanotechnology applications explore reduced particle sizes that enable new incorporation methods and enhanced dispersion characteristics.

Smart material integration represents an emerging trend where strontium aluminate glow powder combines with other functional materials to create responsive systems. Temperature-sensitive formulations change emission characteristics based on environmental conditions, while pH-responsive variants modify brightness in response to chemical exposure, expanding application possibilities into sensor and indicator technologies.

Market Growth Projections

Industry analysts project continued growth in strontium aluminate glow powder demand driven by expanding safety regulations, increased environmental consciousness, and growing consumer awareness of sustainable lighting alternatives. Automotive industry adoption for instrument panels and safety features represents a significant growth opportunity, while architectural applications continue expanding in both commercial and residential sectors.

Supply chain evolution includes vertical integration by major suppliers to secure raw material access and improve cost competitiveness. New production facilities in strategic locations aim to serve regional markets more effectively while reducing transportation costs and delivery lead times. Technology transfer and licensing agreements facilitate capacity expansion without requiring extensive capital investments from established manufacturers.

FAQ

What factors determine the quality of strontium aluminate glow powder

Quality assessment of strontium aluminate glow powder depends on several measurable parameters including initial brightness intensity, afterglow duration, particle size uniformity, and chemical purity levels. Laboratory testing using standardized protocols measures these characteristics objectively, while supplier certifications and quality management systems provide assurance of consistent production processes. Customer references and performance data from actual applications offer practical validation of claimed specifications and long-term reliability.

How do I calculate the right quantity for my specific application

Quantity calculations for strontium aluminate glow powder depend on the intended application, desired brightness level, substrate characteristics, and incorporation method. Typical loading ratios range from five to thirty percent by weight depending on performance requirements and cost considerations. Technical consultation with suppliers helps optimize material usage while achieving desired luminescent performance, often resulting in more efficient use of the phosphorescent compound than initial estimates suggest.

What storage and handling requirements apply to these materials

Proper storage of strontium aluminate glow powder requires dry, cool conditions away from direct sunlight to maintain optimal performance characteristics over extended periods. Moisture absorption can degrade luminescent properties, making sealed containers and controlled humidity environments important for long-term storage. Handling procedures follow standard industrial hygiene practices for fine particles, including appropriate personal protective equipment and dust control measures during processing and incorporation activities.

Can strontium aluminate glow powder be customized for specific applications

Leading suppliers offer extensive customization options for strontium aluminate glow powder including particle size modification, color tuning, brightness optimization, and performance enhancement for specific environmental conditions. Custom formulation development typically requires minimum order quantities and extended lead times but enables precise matching to application requirements. Collaborative development programs with suppliers often yield proprietary formulations that provide competitive advantages through superior performance characteristics tailored to unique application demands.

Table of Contents

- Understanding Strontium Aluminate Technology and Benefits

- Key Sourcing Considerations for Industrial Buyers

- Evaluating Supplier Capabilities and Technical Support

- Cost Analysis and Value Optimization

- Regional Supplier Landscape and Selection Criteria

- Application-Specific Sourcing Strategies

- Future Trends and Market Evolution

- FAQ