The demand for innovative materials that combine functionality with visual appeal has driven significant advancements in polymer technology. Luminescent thermoplastic polyurethane represents a breakthrough in creating flexible, durable products that maintain their glow-in-the-dark properties while offering exceptional mechanical performance. These specialized materials are transforming industries from consumer electronics to safety equipment, providing manufacturers with unprecedented opportunities to develop products that capture attention both day and night.

Modern manufacturing processes have enabled the integration of phosphorescent compounds into TPU matrices, creating materials that absorb ambient light during the day and emit a visible glow for hours after darkness falls. This technology has opened new possibilities for product designers seeking to enhance safety features, create distinctive branding elements, or develop entertainment products that engage users in unique ways. The versatility of luminescent TPU extends beyond simple glow effects, offering engineers the ability to customize intensity, duration, and color characteristics to meet specific application requirements.

Understanding Luminescent TPU Technology

Phosphorescent Compound Integration

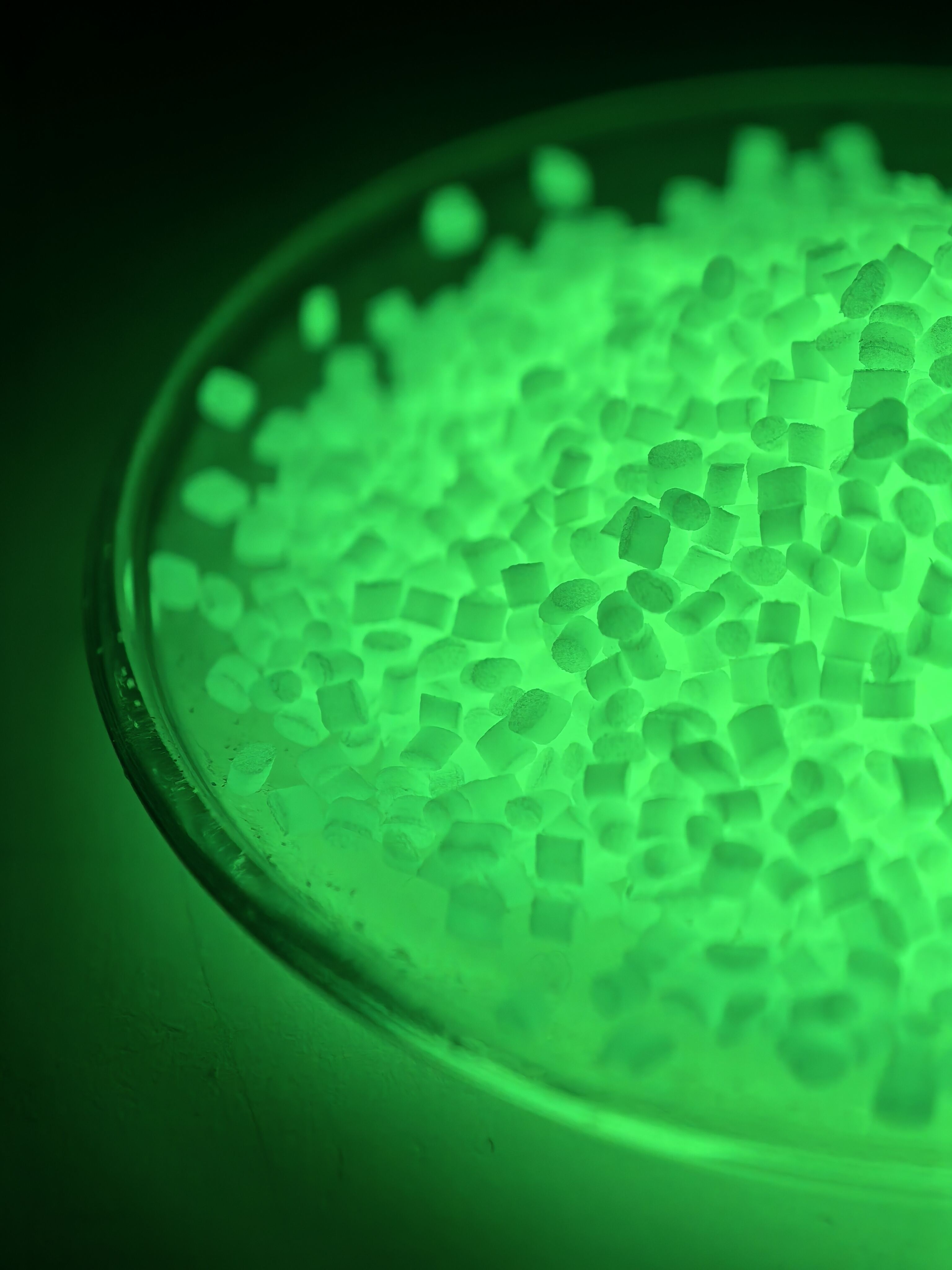

The foundation of luminescent TPU lies in the careful incorporation of phosphorescent materials into the polymer matrix. These compounds, typically based on strontium aluminate or zinc sulfide formulations, are engineered to absorb photons from various light sources and store this energy for gradual release. The integration process requires precise control of particle size distribution and loading levels to ensure optimal glow performance without compromising the material's mechanical properties. Advanced manufacturing techniques allow for uniform dispersion of these compounds throughout the TPU structure, preventing agglomeration and ensuring consistent luminescent behavior across the entire product.

The selection of appropriate phosphorescent compounds depends on the intended application and performance requirements. Strontium aluminate-based systems offer superior brightness and longer afterglow duration, making them ideal for safety applications and high-visibility products. Zinc sulfide formulations, while offering shorter glow times, provide cost-effective solutions for decorative applications and consumer products. The choice between these systems significantly impacts the final product's performance characteristics and manufacturing considerations.

Material Processing Considerations

Manufacturing luminescent TPU requires careful attention to processing parameters to maintain both the integrity of the phosphorescent compounds and the desired material properties. Temperature control during extrusion and molding processes becomes critical, as excessive heat can degrade the luminescent particles and reduce glow performance. Processing equipment must be designed to handle the abrasive nature of phosphorescent fillers, which can cause increased wear on machinery components compared to standard TPU processing.

Quality control measures must account for the unique characteristics of luminescent materials, including glow intensity testing, color consistency evaluation, and long-term stability assessment. These materials require specialized testing protocols that simulate real-world charging and discharge cycles to ensure consistent performance over the product's intended lifespan. Environmental factors such as humidity, temperature fluctuations, and UV exposure can affect luminescent performance, necessitating comprehensive testing regimens during development and production phases.

Applications in Consumer Products

Wearable Technology Integration

The flexibility and durability of luminescent TPU make it an excellent choice for wearable technology applications where traditional rigid glow-in-the-dark materials would be impractical. Watch bands, fitness trackers, and smartphone cases benefit from the material's ability to conform to curved surfaces while maintaining their luminescent properties. The biocompatible nature of properly formulated TPU ensures safe skin contact, making it suitable for extended wear applications such as medical monitoring devices and sports equipment.

Design flexibility allows manufacturers to create complex geometries and intricate patterns that would be impossible with traditional luminescent materials. The material can be processed through injection molding, extrusion, and 3D printing techniques, enabling rapid prototyping and customization for specific market segments. Color options extend beyond the traditional green glow, with blue, orange, and multi-color formulations available to match brand aesthetics and user preferences.

Automotive and Transportation Safety

Automotive applications represent a growing market for luminescent TPU, particularly in safety-critical components that must remain visible during power outages or emergency situations. Dashboard elements, door handles, and emergency equipment housings benefit from the material's ability to provide passive illumination without requiring electrical power. The automotive industry's stringent requirements for durability and environmental resistance align well with TPU's inherent properties, making it suitable for both interior and exterior applications.

Transportation infrastructure applications include bicycle components, pedestrian safety gear, and marine equipment where visibility in low-light conditions is essential. The material's resistance to weathering and UV degradation ensures long-term performance in outdoor environments, while its flexibility allows for integration into moving components and wearable safety equipment. These applications often require specific color formulations to comply with safety regulations and visibility standards.

Industrial and Commercial Applications

Safety and Emergency Equipment

Industrial safety applications leverage the unique properties of luminescent TPU to create equipment that remains visible during power failures or emergency evacuation scenarios. Fire safety equipment, emergency exit markers, and industrial warning devices benefit from the material's ability to provide reliable illumination without depending on external power sources. The durability of TPU ensures that these critical safety components maintain their performance even in harsh industrial environments characterized by temperature extremes, chemical exposure, and mechanical stress.

Manufacturing facilities utilize luminescent TPU components in machinery guards, safety barriers, and personal protective equipment where visibility is crucial for worker safety. The material's impact resistance and flexibility make it suitable for applications where traditional brittle luminescent materials would fail under mechanical stress. Integration into existing safety systems can be accomplished through standard manufacturing processes, allowing for cost-effective upgrades to existing equipment.

Marine and Outdoor Equipment

Marine environments present unique challenges for luminescent materials, requiring exceptional resistance to saltwater corrosion, UV exposure, and temperature cycling. Luminescent TPU formulations designed for marine applications incorporate specialized additives to enhance chemical resistance and prevent degradation of both the polymer matrix and phosphorescent compounds. Navigation aids, safety equipment, and deck hardware benefit from the material's ability to maintain luminescent performance in demanding oceanic conditions.

Outdoor recreational equipment applications include camping gear, hiking accessories, and sports equipment where reliable low-light visibility enhances user safety and convenience. The material's flexibility allows for integration into fabric structures, inflatable components, and articulating mechanisms that would be incompatible with rigid luminescent alternatives. Weather resistance ensures consistent performance across diverse climatic conditions, from arctic cold to tropical heat and humidity.

Manufacturing Considerations and Quality Control

Processing Parameter Optimization

Successful manufacturing of luminescent TPU products requires careful optimization of processing parameters to balance material flow, mechanical properties, and luminescent performance. Injection molding parameters must be adjusted to accommodate the increased viscosity and abrasive nature of phosphorescent-filled compounds. Mold design considerations include gate placement, runner sizing, and cooling channel configuration to ensure uniform material distribution and minimize stress concentrations that could affect long-term performance.

Extrusion processes benefit from specialized screw designs that provide gentle mixing while preventing excessive shear that could damage phosphorescent particles. Temperature profiles must be carefully controlled throughout the processing equipment to maintain material properties while preventing thermal degradation of sensitive compounds. Quality monitoring systems should track key parameters such as melt temperature, pressure, and residence time to ensure consistent output quality and luminescent performance.

Testing and Validation Protocols

Comprehensive testing protocols for luminescent TPU products must address both mechanical properties and photoluminescent performance characteristics. Standard mechanical testing includes tensile strength, elongation, hardness, and tear resistance measurements, which may be affected by the presence of phosphorescent fillers. Specialized luminescent testing evaluates initial brightness, afterglow duration, color coordinates, and charging efficiency under various light sources.

Long-term stability testing simulates real-world aging conditions through accelerated exposure to UV radiation, temperature cycling, and chemical environments. These tests help predict product lifespan and identify potential failure modes that could affect luminescent performance over time. Environmental testing protocols should reflect the intended application environment, with marine applications requiring salt spray exposure and automotive applications necessitating thermal cycling representative of vehicle operating conditions.

Future Developments and Market Trends

Advanced Phosphorescent Formulations

Research into next-generation phosphorescent compounds focuses on improving brightness, extending glow duration, and expanding color options for luminescent TPU applications. Rare earth-doped compounds offer enhanced performance characteristics, including improved quantum efficiency and resistance to environmental degradation. These advanced formulations enable the development of products with extended operational lifespans and superior performance in challenging environments.

Nanotechnology applications in luminescent materials promise significant improvements in dispersion quality and interfacial adhesion between phosphorescent particles and the TPU matrix. Surface-modified nanoparticles can reduce agglomeration tendencies while enhancing the mechanical properties of the composite material. These developments support the creation of thinner, more flexible products that maintain high luminescent intensity and durability.

Smart Material Integration

The convergence of luminescent TPU technology with smart material concepts opens new possibilities for responsive products that adapt to environmental conditions. Temperature-sensitive formulations can alter their luminescent properties based on ambient conditions, providing visual feedback for temperature monitoring applications. Integration with electronic components enables hybrid products that combine passive luminescent features with active electronic functionality.

Biodegradable luminescent TPU formulations address growing environmental concerns while maintaining the performance characteristics required for demanding applications. These materials support the development of sustainable products that can decompose safely at end-of-life while providing reliable luminescent performance throughout their intended service period. Market demand for environmentally responsible materials continues to drive innovation in this area, with several promising formulations currently under development.

FAQ

How long does the glow effect last in luminescent TPU products

The glow duration in luminescent TPU varies significantly based on the phosphorescent compound used and charging conditions. High-quality strontium aluminate formulations typically provide visible glow for 8-12 hours after full charging with bright light, while zinc sulfide-based systems offer 1-3 hours of visible afterglow. Charging time requirements range from 15 minutes to several hours depending on light intensity, with direct sunlight providing the most efficient charging. Environmental factors such as temperature and humidity can affect glow duration and intensity.

What are the temperature limitations for luminescent TPU applications

Luminescent TPU maintains its mechanical properties and glow characteristics across a broad temperature range, typically from -40°C to +80°C for continuous operation. Short-term exposure to higher temperatures up to 120°C is generally acceptable, though prolonged exposure may degrade phosphorescent performance. Cold temperature performance remains excellent, with flexibility maintained even at sub-zero conditions. Processing temperatures during manufacturing must be carefully controlled to prevent thermal damage to phosphorescent compounds, typically staying below 200°C during melt processing.

Can luminescent TPU be recycled or reprocessed

Recycling of luminescent TPU presents unique challenges due to the presence of inorganic phosphorescent fillers, but reprocessing is possible with proper handling techniques. Mechanical recycling through shredding and re-melting can maintain acceptable material properties, though some loss of luminescent intensity may occur due to particle damage during processing. Chemical recycling methods show promise for recovering both the TPU matrix and phosphorescent compounds separately. Contamination control becomes critical during recycling operations to prevent mixing with other polymer types that could compromise material performance.

How does UV exposure affect luminescent TPU performance over time

Extended UV exposure can gradually degrade both the TPU matrix and phosphorescent compounds, leading to reduced mechanical properties and diminished glow performance. UV stabilizers and antioxidants are commonly added to outdoor formulations to extend service life, with properly formulated materials maintaining acceptable performance for several years of outdoor exposure. Indoor applications typically show minimal degradation over many years, as UV exposure levels are significantly lower. Regular charging with natural or artificial light can help maintain optimal luminescent performance throughout the product's service life.