Industrial applications increasingly demand materials that combine exceptional durability with unique functional properties. Glow-in-the-dark thermoplastic polyurethane represents a revolutionary advancement in polymer technology, offering manufacturers and engineers a versatile solution for applications requiring both mechanical performance and photoluminescent capabilities. This innovative material bridges the gap between traditional thermoplastic polyurethanes and specialized luminescent compounds, creating opportunities across multiple industries from automotive to consumer electronics. Understanding the fundamental properties and manufacturing advantages of glow-in-the-dark thermoplastic polyurethane enables informed decision-making for product developers seeking enhanced functionality without compromising structural integrity.

Chemical Composition and Molecular Structure

Polymer Matrix Foundation

The base matrix of glow-in-the-dark thermoplastic polyurethane consists of segmented block copolymers containing hard and soft segments that provide the material's characteristic elastomeric properties. The hard segments typically comprise aromatic diisocyanates and chain extenders, while soft segments include polyester or polyether polyols that contribute to flexibility and processability. This segmented structure enables the material to maintain excellent mechanical properties while accommodating photoluminescent additives without compromising the polymer's integrity. The molecular weight distribution and segment ratio directly influence both the physical properties and the luminescent performance of the final compound.

Incorporation of photoluminescent pigments requires careful consideration of polymer compatibility and dispersion uniformity. The thermoplastic nature allows for melt processing while maintaining the photoluminescent particles in stable suspension throughout the polymer matrix. Advanced formulation techniques ensure that the luminescent compounds remain evenly distributed and maintain their charging and emission characteristics even after multiple thermal processing cycles. This chemical stability makes glow-in-the-dark thermoplastic polyurethane suitable for injection molding, extrusion, and other conventional thermoplastic processing methods.

Photoluminescent Integration Technology

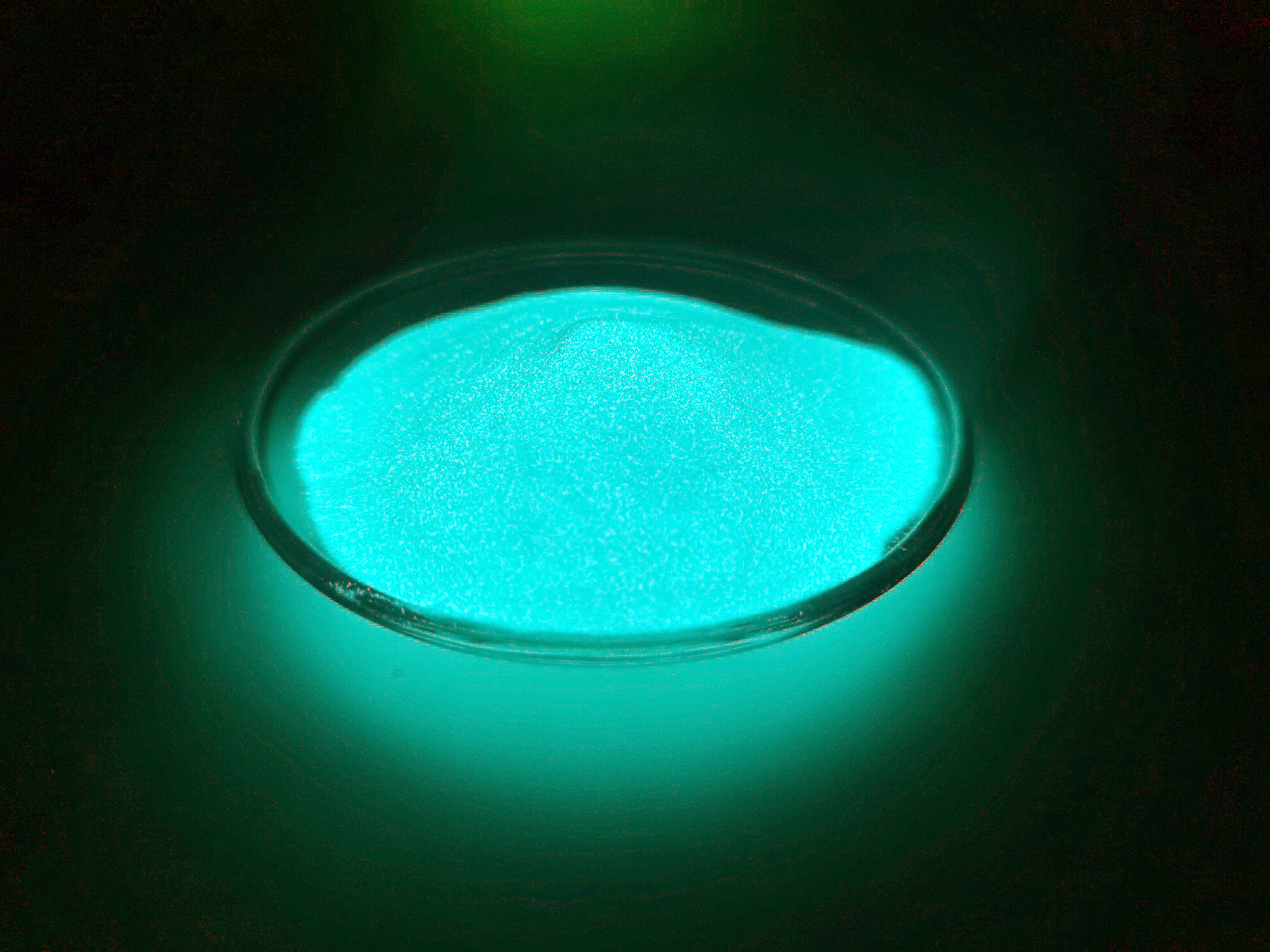

The photoluminescent properties derive from carefully selected phosphorescent pigments that absorb ambient light energy and re-emit it over extended periods. These pigments typically consist of alkaline earth aluminates doped with rare earth elements, creating long-lasting afterglow effects that can persist for hours after the initial light exposure. The integration process requires precise control of particle size distribution and surface treatment to prevent agglomeration and ensure optimal light absorption and emission characteristics. Modern glow-in-the-dark thermoplastic polyurethane formulations achieve loading levels that maximize luminescence while preserving the base polymer's processing characteristics.

Surface modification of photoluminescent particles enhances compatibility with the polyurethane matrix and improves dispersion quality during compounding. Silane coupling agents and other surface treatments create chemical bonds between the inorganic phosphors and the organic polymer, resulting in improved mechanical properties and reduced particle migration during service. This enhanced integration ensures consistent luminescent performance throughout the material's service life and maintains the visual uniformity required for high-quality applications.

Physical and Mechanical Properties

Durometer Range and Flexibility Characteristics

Glow-in-the-dark thermoplastic polyurethane exhibits exceptional versatility in hardness range, typically spanning from Shore A 60 to Shore D 75, allowing manufacturers to select optimal firmness for specific applications. The material maintains excellent elastomeric recovery even at lower durometer ratings, demonstrating superior resilience compared to conventional thermoplastics. Tensile strength values often exceed 35 MPa while maintaining elongation at break greater than 400%, providing the flexibility required for dynamic applications such as gaskets, seals, and flexible components. The relationship between hardness and luminescent intensity requires optimization during formulation to achieve the desired balance of mechanical performance and photoluminescent output.

Temperature stability remains consistent across the operational range, with glass transition temperatures typically occurring well below normal service conditions. The material demonstrates excellent low-temperature flexibility, maintaining elastomeric properties down to -40°C in properly formulated grades. Compression set resistance ensures dimensional stability under sustained loading conditions, while the thermoplastic nature enables recycling and reprocessing capabilities that support sustainable manufacturing practices. These combined properties make glow-in-the-dark thermoplastic polyurethane ideal for applications requiring both durability and visual functionality.

Chemical Resistance and Environmental Stability

Chemical resistance properties of glow-in-the-dark thermoplastic polyurethane depend on the specific polyol type and hard segment chemistry employed in the formulation. Polyether-based grades generally demonstrate superior hydrolytic stability and resistance to microbial attack, making them suitable for outdoor and marine applications. Polyester-based formulations offer enhanced resistance to oils, solvents, and aromatic hydrocarbons while maintaining excellent mechanical properties under chemical exposure. The photoluminescent additives are carefully selected for chemical inertness, ensuring that luminescent performance remains stable even in challenging chemical environments.

Ultraviolet radiation resistance represents a critical performance factor for outdoor applications of glow-in-the-dark thermoplastic polyurethane. Advanced formulations incorporate UV stabilizers and antioxidants that protect both the polymer matrix and the photoluminescent pigments from degradation. Accelerated weathering tests demonstrate minimal color change and luminescence loss after extended UV exposure, confirming suitability for architectural, automotive, and marine applications. The material's inherent stability combined with protective additives ensures long-term performance in demanding environmental conditions.

Manufacturing Advantages and Processing Benefits

Melt Processing Efficiency

The thermoplastic nature of glow-in-the-dark thermoplastic polyurethane enables efficient processing using conventional injection molding, extrusion, and blow molding equipment without requiring specialized handling procedures. Processing temperatures typically range from 180°C to 220°C, well within the capabilities of standard thermoplastic processing equipment. Melt flow characteristics remain consistent and predictable, allowing for precise control of wall thickness and dimensional accuracy in complex geometries. The material's relatively low viscosity at processing temperatures facilitates complete mold filling while minimizing injection pressures and cycle times.

Regrind incorporation capabilities significantly reduce material waste and support sustainable manufacturing practices. Post-consumer and post-industrial scrap can be reprocessed multiple times without significant degradation of mechanical or luminescent properties when proper handling procedures are followed. This recycling capability provides substantial cost advantages over thermoset polyurethane alternatives while supporting environmental stewardship objectives. Quality control procedures ensure consistent luminescent performance in products containing recycled content.

Tooling and Equipment Compatibility

Existing thermoplastic processing equipment requires minimal modification to accommodate glow-in-the-dark thermoplastic polyurethane, reducing capital investment requirements for manufacturers transitioning from conventional materials. Standard screw designs and barrel configurations provide adequate mixing and homogenization of the photoluminescent additives during processing. Mold design considerations include proper venting to prevent gas traps and ensure complete filling of thin-walled sections where luminescent visibility is critical. Temperature control systems maintain optimal processing conditions while preventing thermal degradation of both the polymer matrix and photoluminescent components.

Color matching and consistency requirements demand careful attention to processing parameters and material handling procedures. Batch-to-batch variations in luminescent intensity can be minimized through proper temperature control and residence time management during processing. Quality assurance protocols include both daylight color matching and afterglow intensity measurements to ensure consistent product appearance and performance. These standardized procedures enable reliable production of high-quality glow-in-the-dark thermoplastic polyurethane components.

Industrial Applications and Market Opportunities

Safety and Emergency Applications

Emergency egress systems represent a primary application area for glow-in-the-dark thermoplastic polyurethane, where the material's durability and long-lasting luminescence provide critical safety functions. Stair nosings, handrails, and exit pathway markings fabricated from this material maintain visibility during power outages and emergency situations. The material's resistance to cleaning chemicals and mechanical wear ensures reliable performance in high-traffic commercial and institutional buildings. Building codes increasingly recognize photoluminescent materials as acceptable alternatives to electrical emergency lighting systems, expanding market opportunities for glow-in-the-dark thermoplastic polyurethane components.

Marine safety applications benefit from the material's resistance to saltwater corrosion and UV degradation while providing essential visibility in low-light conditions. Life jacket components, deck markings, and safety equipment housings manufactured from glow-in-the-dark thermoplastic polyurethane enhance visibility without requiring electrical power or battery maintenance. The material's flexibility and impact resistance make it ideal for safety applications where conventional rigid photoluminescent materials might fail under mechanical stress.

Consumer Electronics and Automotive Integration

Consumer electronics manufacturers increasingly specify glow-in-the-dark thermoplastic polyurethane for device housings, buttons, and decorative elements that enhance user experience in low-light environments. The material's excellent dimensional stability and surface finish quality meet the stringent requirements of modern electronic device manufacturing. Processing compatibility with insert molding and overmolding techniques enables integration with metal and plastic substrates commonly used in electronic assemblies. The aesthetic appeal of subtle photoluminescent effects combined with functional benefits drives adoption in premium consumer products.

Automotive applications leverage both the functional and aesthetic properties of glow-in-the-dark thermoplastic polyurethane in interior and exterior components. Dashboard elements, door handles, and safety equipment benefit from enhanced visibility while maintaining the durability required for automotive service life. The material's chemical resistance to automotive fluids and temperature stability across the automotive operating range ensure reliable performance in demanding vehicular environments. Regulatory compliance with automotive material specifications facilitates adoption in original equipment manufacturer applications.

Performance Optimization and Quality Control

Luminescent Intensity Enhancement

Optimizing luminescent performance in glow-in-the-dark thermoplastic polyurethane requires careful balance between phosphorescent pigment loading and mechanical property retention. Higher pigment concentrations increase initial brightness and afterglow duration but may compromise processability and mechanical strength. Advanced formulation techniques enable loading optimization that maximizes luminescent output while maintaining acceptable physical properties for specific applications. Particle size distribution control ensures uniform light absorption and emission characteristics throughout molded components.

Charging efficiency depends on both the phosphorescent pigment selection and the polymer matrix transparency to activating wavelengths. Clear or lightly tinted base polymers maximize light transmission to embedded phosphors, while surface treatments can enhance light coupling efficiency. Quality control procedures include standardized charging protocols and luminance decay measurements to ensure consistent performance across production lots. These measurements enable optimization of both material formulation and processing parameters for maximum luminescent effectiveness.

Long-term Stability Assessment

Accelerated aging protocols evaluate the long-term stability of both mechanical and luminescent properties in glow-in-the-dark thermoplastic polyurethane applications. Thermal aging studies assess property retention under elevated temperature exposure, while UV exposure testing evaluates outdoor durability and photoluminescent stability. Cyclic loading tests determine fatigue resistance and dimensional stability under repeated mechanical stress. These comprehensive evaluation methods ensure reliable performance predictions for various service environments and application requirements.

Chemical compatibility testing validates performance in specific application environments, including exposure to cleaning agents, industrial chemicals, and environmental contaminants. Stress crack resistance evaluation under chemical exposure ensures long-term reliability in demanding applications. The combination of mechanical and chemical testing protocols provides comprehensive validation of glow-in-the-dark thermoplastic polyurethane performance for critical applications where failure could compromise safety or functionality.

FAQ

What is the typical afterglow duration for glow-in-the-dark thermoplastic polyurethane

The afterglow duration for glow-in-the-dark thermoplastic polyurethane typically ranges from 8 to 12 hours, depending on the phosphorescent pigment type and loading level. High-performance formulations using strontium aluminate phosphors can maintain visible luminescence for up to 12 hours after a 10-minute light exposure. The initial brightness decays exponentially, with the highest intensity occurring within the first hour after light exposure. Proper charging with natural or artificial light sources optimizes both initial brightness and total afterglow duration.

How does processing temperature affect the luminescent properties

Processing temperatures between 180°C and 220°C generally do not adversely affect the photoluminescent properties of glow-in-the-dark thermoplastic polyurethane when proper handling procedures are followed. Excessive temperatures above 240°C or prolonged residence times can cause thermal degradation of phosphorescent pigments, resulting in reduced brightness and shorter afterglow duration. Proper temperature control and minimized residence time during processing ensure optimal retention of luminescent performance. Quality control testing includes luminance measurements on processed samples to verify property retention throughout manufacturing.

Can glow-in-the-dark thermoplastic polyurethane be recycled

Yes, glow-in-the-dark thermoplastic polyurethane can be recycled and reprocessed multiple times while maintaining acceptable mechanical and luminescent properties. Proper separation and cleaning of recycled material ensure optimal performance in subsequent processing cycles. Regrind content up to 25% typically shows minimal impact on luminescent intensity or mechanical properties. Higher recycled content may require adjustment of processing parameters and may show gradual reduction in luminescent performance. Quality control procedures monitor both mechanical properties and luminescent intensity to ensure recycled material meets application requirements.

What safety considerations apply when handling this material

Glow-in-the-dark thermoplastic polyurethane requires standard thermoplastic handling procedures with particular attention to dust control during material handling and processing. The phosphorescent pigments are generally non-toxic but should not be inhaled as fine particles. Proper ventilation during processing prevents accumulation of thermal decomposition products. Personal protective equipment including safety glasses and dust masks should be worn during material handling operations. Material safety data sheets provide comprehensive information on safe handling, storage, and disposal procedures for specific formulations.