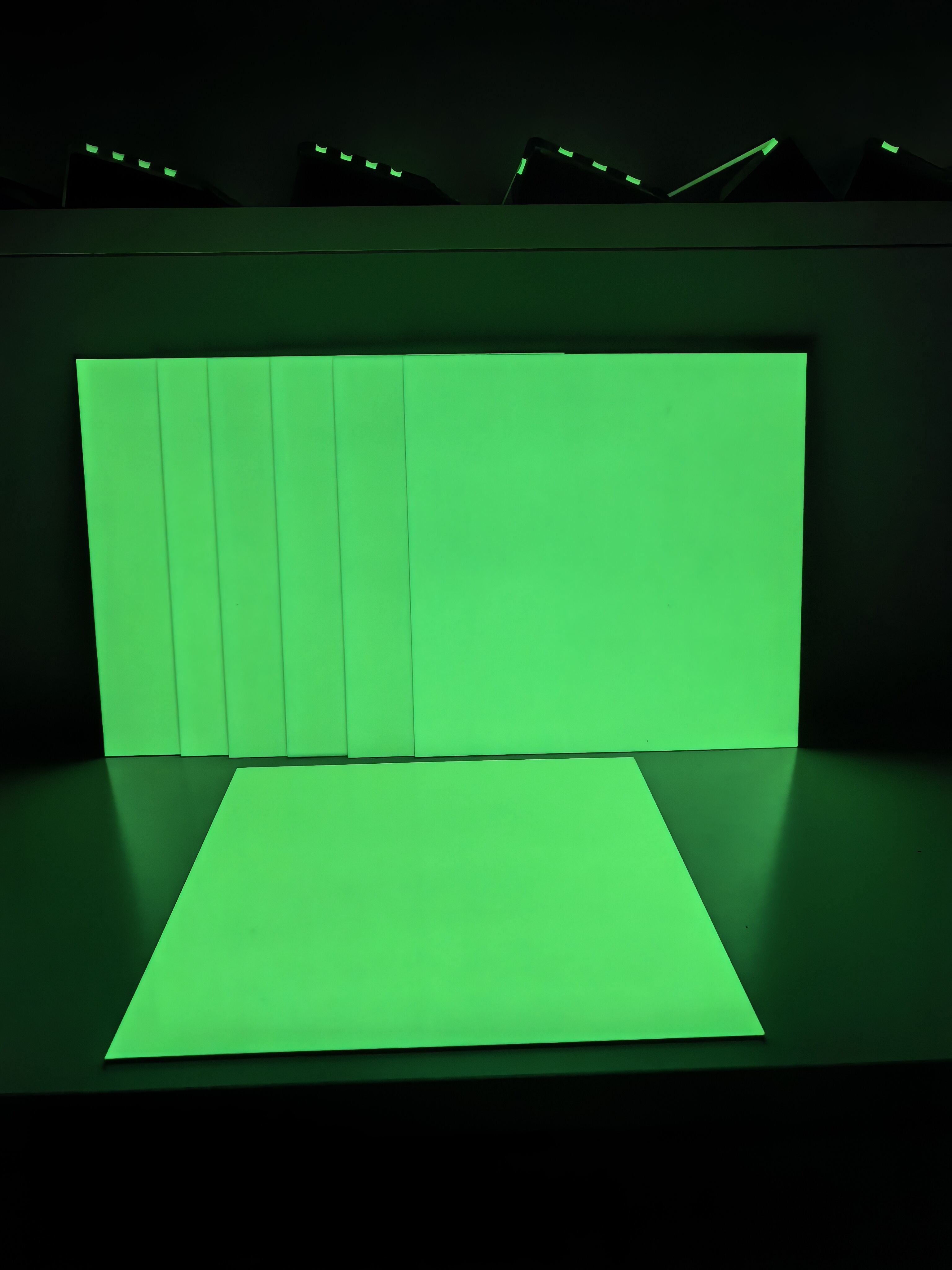

Photoluminescent pigments have revolutionized numerous industries by providing sustainable lighting solutions that eliminate the need for external power sources. These remarkable materials absorb ambient light during the day and emit a distinctive glow in darkness, making them invaluable for safety applications, decorative purposes, and emergency signaling systems. Understanding the intricate relationship between particle sizes and color variations in photoluminescent pigments is essential for professionals seeking to optimize their applications and achieve desired performance outcomes.

The science behind photoluminescent pigments involves complex crystalline structures that determine both their luminous intensity and color characteristics. These materials, primarily composed of alkaline earth aluminates doped with rare earth elements, exhibit unique properties that vary significantly based on their particle size distribution and chemical composition. Modern manufacturing techniques have enabled precise control over these parameters, allowing for customized solutions across diverse industrial applications.

Understanding Particle Size Distribution in Photoluminescent Materials

Micron-Level Classifications and Performance Impact

Particle size distribution represents one of the most critical factors influencing the performance characteristics of photoluminescent pigments. Manufacturers typically classify these materials into distinct categories ranging from ultra-fine particles measuring 1-5 microns to coarser grades extending up to 75 microns. Each size category exhibits specific advantages and limitations that directly impact their suitability for various applications.

Fine particle photoluminescent pigments, typically ranging from 1-15 microns, offer superior dispersion properties and enhanced surface smoothness when incorporated into coatings and plastics. These materials provide excellent coverage with minimal settling, making them ideal for screen printing applications and thin-film formulations. However, their reduced particle mass may result in slightly diminished glow intensity compared to larger particles.

Medium-grade particles, spanning 15-35 microns, strike an optimal balance between dispersion characteristics and luminous output. This size range has become increasingly popular in commercial applications where both performance and processing ease are paramount. The particles maintain sufficient mass for robust light emission while remaining manageable during manufacturing processes.

Coarse Particle Applications and Benefits

Larger photoluminescent pigments, measuring 35-75 microns, deliver maximum brightness and extended glow duration due to their increased material volume per particle. These coarse grades excel in applications requiring intense luminosity, such as emergency evacuation systems and high-visibility safety markings. Their substantial size provides greater light storage capacity, resulting in prolonged afterglow periods that can extend beyond twelve hours.

The selection of appropriate particle sizes depends heavily on the intended application method and final product requirements. Spray applications typically favor finer particles to prevent nozzle clogging, while brush-applied coatings can accommodate larger particles without processing difficulties. Understanding these relationships enables formulators to optimize their products for specific performance criteria.

Manufacturing considerations also play a crucial role in particle size selection. Injection molding processes generally require finer particles to ensure uniform distribution throughout the polymer matrix, while compression molding can successfully incorporate larger particles. The interaction between particle size and processing temperature must be carefully evaluated to prevent degradation of the luminescent properties.

Color Variations and Chemical Composition Factors

Primary Color Categories and Their Applications

The color spectrum available in photoluminescent pigments has expanded dramatically through advances in rare earth doping technologies. Traditional yellow-green emissions, achieved through europium-activated strontium aluminate formulations, remain the most efficient and widely used variants. These materials provide the highest luminous intensity and longest afterglow duration, making them the preferred choice for safety-critical applications.

Blue-emitting photoluminescent pigments, typically based on europium-doped barium magnesium aluminate systems, offer unique aesthetic possibilities for decorative applications. While their initial brightness may be lower than yellow-green variants, blue pigments provide distinctive visual appeal in architectural lighting and artistic installations. The cool color temperature creates striking contrast effects when combined with conventional lighting systems.

Aqua and purple formulations represent newer developments in photoluminescent technology, utilizing advanced crystal engineering to achieve these specific color outputs. These specialty colors command premium pricing due to their complex manufacturing requirements and limited production volumes. Their applications focus primarily on high-value decorative markets and specialty industrial uses where color differentiation provides functional benefits.

Color Stability and Environmental Factors

Color consistency in photoluminescent pigments depends on several environmental and processing factors that can influence their spectral output over time. Temperature exposure during manufacturing and end-use conditions significantly affects color stability, with elevated temperatures potentially causing shifts in emission wavelength. Proper formulation with appropriate stabilizers helps maintain color integrity throughout the product lifecycle.

Moisture exposure represents another critical factor affecting color performance in photoluminescent pigments. Hydrolysis reactions can occur at crystal boundaries, leading to gradual degradation of luminous properties and potential color shifts. Advanced encapsulation techniques and hydrophobic treatments have been developed to enhance moisture resistance and extend operational lifespan.

Chemical compatibility with host matrices requires careful consideration when selecting photoluminescent pigments for specific applications. Acidic or basic environments can interact with the crystal structure, potentially altering both color output and brightness levels. Comprehensive compatibility testing ensures optimal performance and prevents unexpected color variations in finished products.

Processing Techniques and Quality Optimization

Manufacturing Methods for Particle Size Control

Controlled crystallization processes represent the foundation of modern photoluminescent pigment manufacturing, enabling precise manipulation of particle size distributions. High-temperature solid-state reactions, typically conducted at temperatures exceeding 1300°C, promote optimal crystal formation while allowing for size control through careful management of heating rates and cooling profiles. These thermal cycles directly influence the final particle characteristics and luminous properties.

Mechanical processing techniques, including ball milling and jet milling, provide post-synthesis methods for achieving specific particle size targets. Ball milling offers cost-effective size reduction with good control over final distributions, though extended processing times may be required to achieve ultra-fine particles. Jet milling provides superior size control and narrow distribution ranges but requires higher energy inputs and specialized equipment.

Classification systems using air separation or screening technologies enable manufacturers to produce tightly controlled particle size fractions from broader distributions. These secondary processing steps add value by providing customers with precisely tailored materials that optimize their specific application requirements. Advanced classification techniques can achieve extremely narrow size distributions that enhance both performance consistency and processing reliability.

Quality Control and Testing Methodologies

Comprehensive quality control protocols ensure consistent performance across production batches of photoluminescent pigments. Particle size analysis using laser diffraction techniques provides detailed distribution data that enables process optimization and quality verification. These measurements must be correlated with actual application performance to establish meaningful specification limits.

Brightness testing protocols, standardized according to international specifications, provide quantitative measures of luminous intensity and afterglow duration. These tests typically involve controlled light exposure followed by calibrated photometric measurements over extended time periods. Consistent testing procedures enable reliable comparison of different products and batch-to-batch quality verification.

Color measurement using spectrophotometric analysis ensures consistency in emission wavelength and color purity. These measurements are particularly critical for applications requiring specific color matching or where multiple batches must provide identical visual appearance. Advanced color measurement techniques can detect subtle variations that might not be apparent to visual inspection.

Industrial Applications and Performance Requirements

Safety and Emergency Systems

Emergency evacuation systems represent one of the most demanding applications for photoluminescent pigments, requiring exceptional brightness levels and extended glow duration. These critical safety applications mandate the use of coarser particle sizes to maximize light output and ensure visibility during power outages. Building codes and safety regulations often specify minimum brightness requirements that influence particle size selection for these applications.

Marine safety applications present unique challenges due to harsh environmental conditions including saltwater exposure and extreme weather. Photoluminescent pigments used in these applications require specialized treatments to enhance corrosion resistance while maintaining luminous performance. Particle size selection must consider both brightness requirements and durability under marine conditions.

Industrial safety marking applications benefit from the versatility of different particle sizes, allowing customization based on viewing distance and ambient lighting conditions. Fine particles excel in detailed graphics and small text, while coarser grades provide maximum visibility for large-scale safety signs and pathway markings. The selection process must balance readability requirements with processing constraints.

Decorative and Architectural Applications

Architectural applications of photoluminescent pigments have expanded significantly as designers seek sustainable lighting solutions that reduce energy consumption. These applications often prioritize color variety and aesthetic appeal over maximum brightness, creating opportunities for specialty formulations with unique particle characteristics. Fine particle grades enable smooth surface finishes that complement modern architectural designs.

Decorative coatings and paints utilize photoluminescent pigments to create dramatic lighting effects in entertainment venues, retail spaces, and residential applications. These markets demand consistent color reproduction and surface appearance, making particle size uniformity a critical quality parameter. Advanced manufacturing techniques enable production of narrow distribution grades that enhance coating uniformity.

Textile applications represent an emerging market for photoluminescent pigments, with fiber incorporation and fabric printing opening new possibilities for functional clothing and decorative materials. These applications require ultra-fine particles that can penetrate fiber structures without compromising material strength or flexibility. Specialized surface treatments may be necessary to ensure wash durability and color retention.

FAQ

What particle size range provides the brightest photoluminescent performance

Coarser particle sizes, typically ranging from 35-75 microns, deliver the brightest photoluminescent performance due to their increased material volume per particle. These larger particles can store more light energy and emit it over longer periods, making them ideal for applications requiring maximum brightness and extended glow duration. However, the optimal size depends on specific application requirements and processing constraints.

How does particle size affect the color appearance of photoluminescent pigments

Particle size primarily influences brightness and glow duration rather than color appearance, which is determined by the chemical composition and rare earth dopants used in the crystal structure. However, very fine particles may appear to have slightly different color characteristics due to light scattering effects and surface area considerations. The base color remains consistent across different particle sizes within the same chemical formulation.

Can different particle sizes be mixed to optimize performance

Yes, blending different particle sizes can optimize performance for specific applications by combining the benefits of each size fraction. Fine particles provide good dispersion and surface coverage, while coarser particles contribute maximum brightness. Custom blends can be formulated to achieve desired balance between processing ease, surface appearance, and luminous intensity, though thorough testing is recommended to ensure compatibility and performance consistency.

What factors should be considered when selecting photoluminescent pigments for specific colors

Color selection should consider application requirements, environmental conditions, and compatibility with host materials. Yellow-green provides maximum brightness and duration, blue offers unique aesthetic appeal, and specialty colors like aqua and purple provide differentiation for specific applications. Factors including temperature stability, moisture resistance, chemical compatibility, and cost must be evaluated alongside color preferences to ensure optimal long-term performance.

Table of Contents

- Understanding Particle Size Distribution in Photoluminescent Materials

- Color Variations and Chemical Composition Factors

- Processing Techniques and Quality Optimization

- Industrial Applications and Performance Requirements

-

FAQ

- What particle size range provides the brightest photoluminescent performance

- How does particle size affect the color appearance of photoluminescent pigments

- Can different particle sizes be mixed to optimize performance

- What factors should be considered when selecting photoluminescent pigments for specific colors